Hebei Zhengtian Fan Manufacturing Co., Ltd.

Contact Us

E-mail:

youtian@hbztfj.com

WhatsApp:

Add:

Renqiu City, Cangzhou City, Hebei province, discuss Bao township Shoulian village east Yi road east

7 minus 41 equals -34.

keyword:

- Description

-

Overview

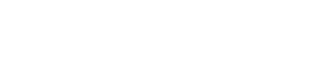

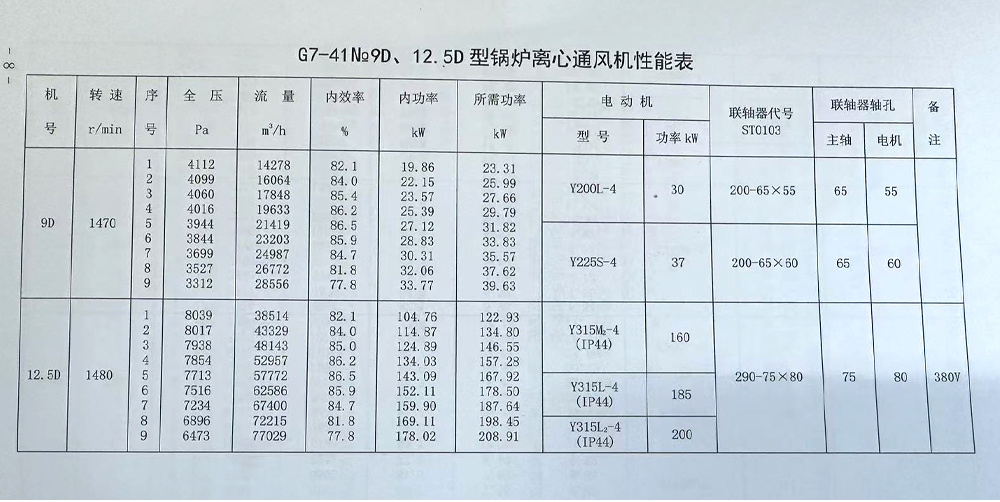

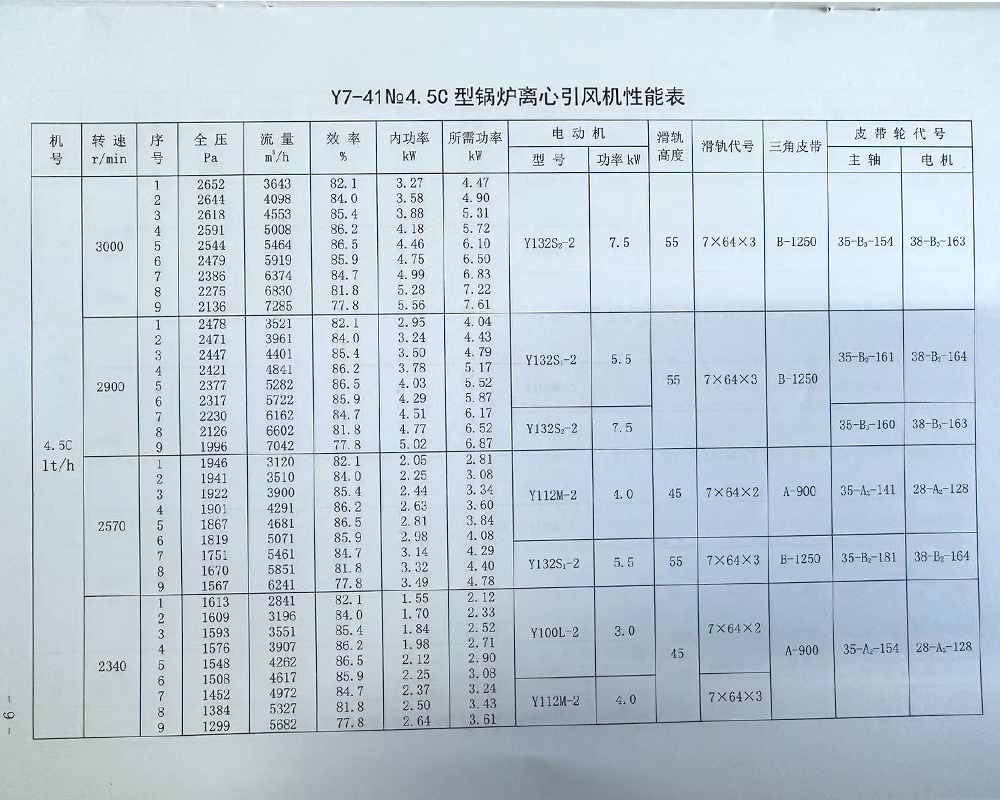

The main features of the G, Y7-41 type industrial boiler induced draft fan are: high fan efficiency, high total pressure, low noise, flat performance curve, and a wide economic operating range. It uses backward curved blades, and the efficiency at the ideal operating point is 86.5% with a noise level (A-weighted) of LS=11.5 decibels. These two indicators are better than those of various existing industrial boiler induced draft fans in the country. If this fan achieves the same flow and pressure as other models, the fan shaft speed can be significantly reduced (generally reduced by 200-800 RPM), which greatly reduces noise and ensures stable and reliable operation.

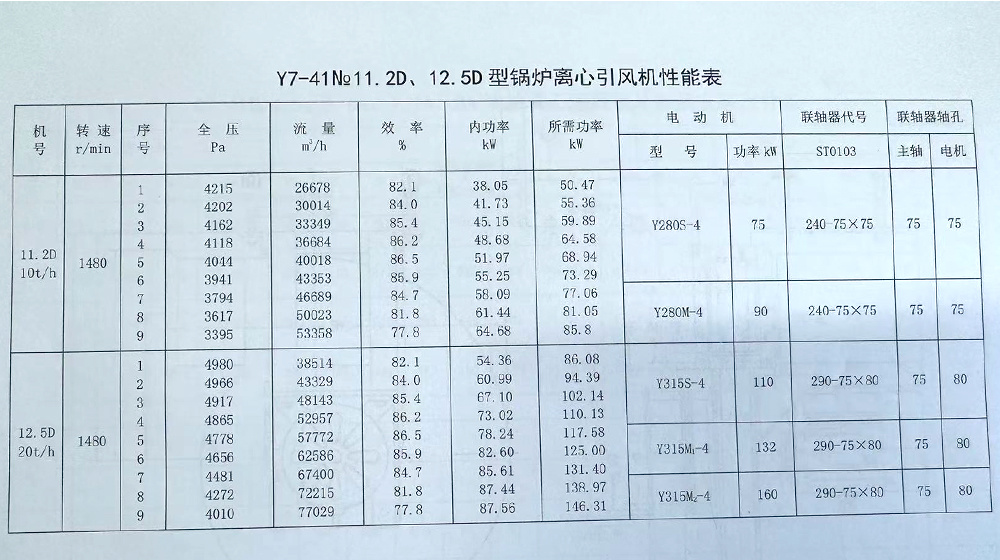

The medium conveyed by the fan is air, with a maximum temperature not exceeding 80°C. The induced draft fan conveys flue gas, and under the same flow conditions, this induced draft fan can increase pressure by more than 30% compared to the original Y5-47 and other boiler induced draft fans. Therefore, it is particularly suitable for industrial boilers with a capacity of 1-20t/h that use spiral pipelines and multi-tube dust collectors.

Type

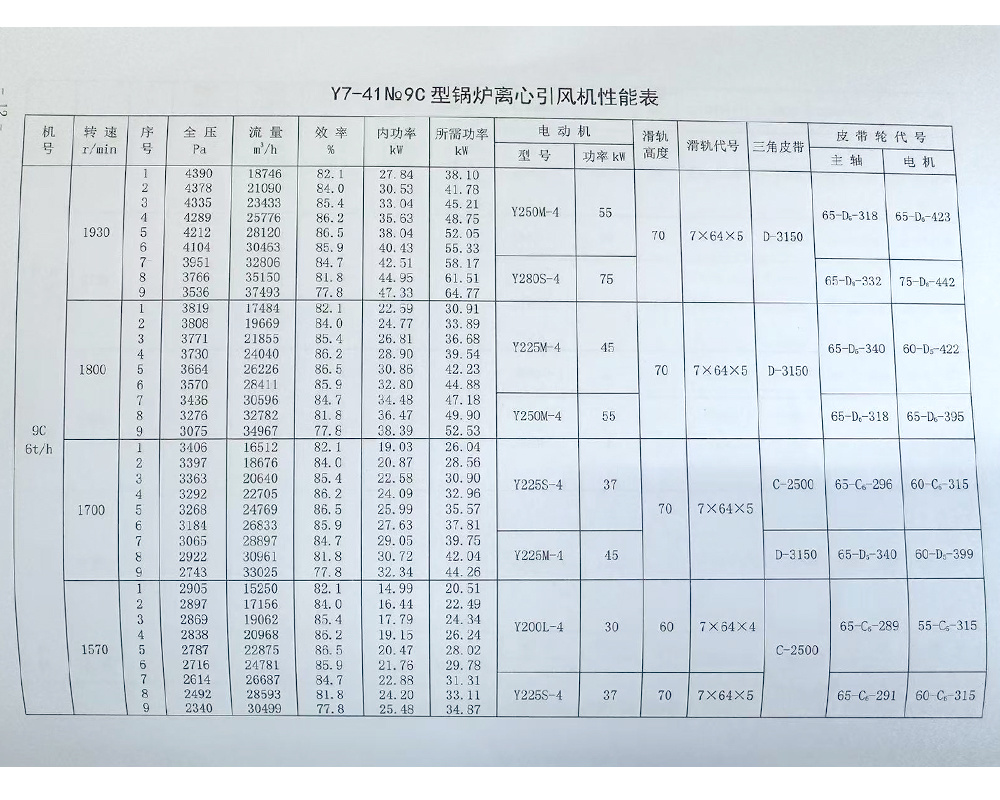

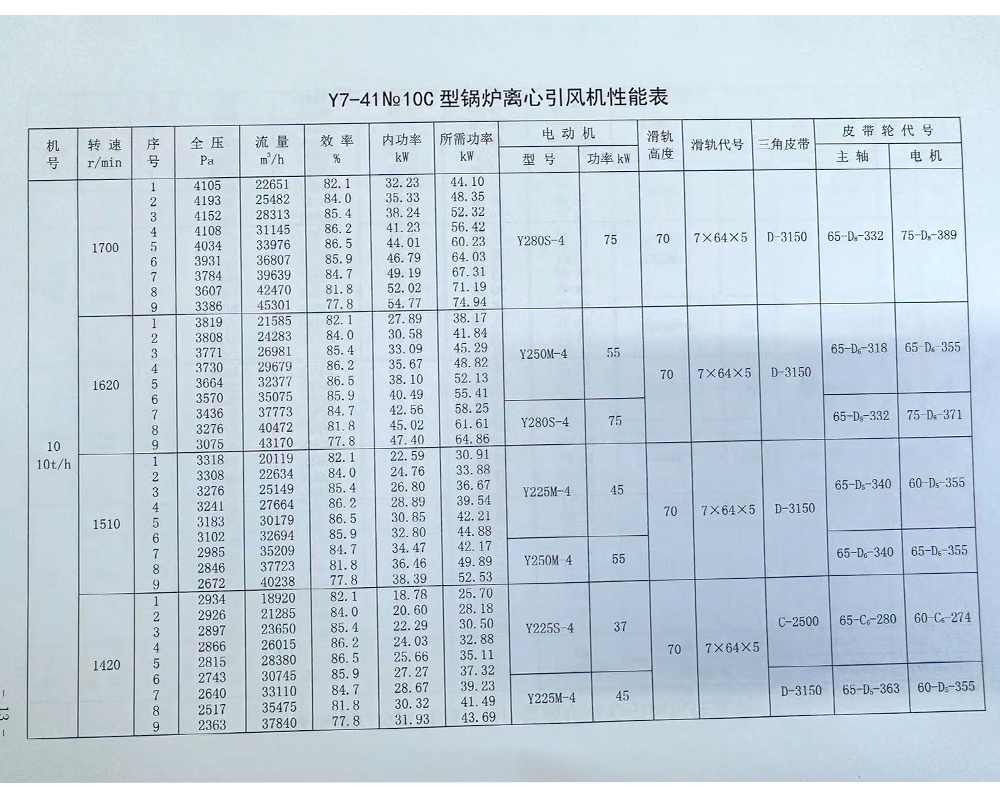

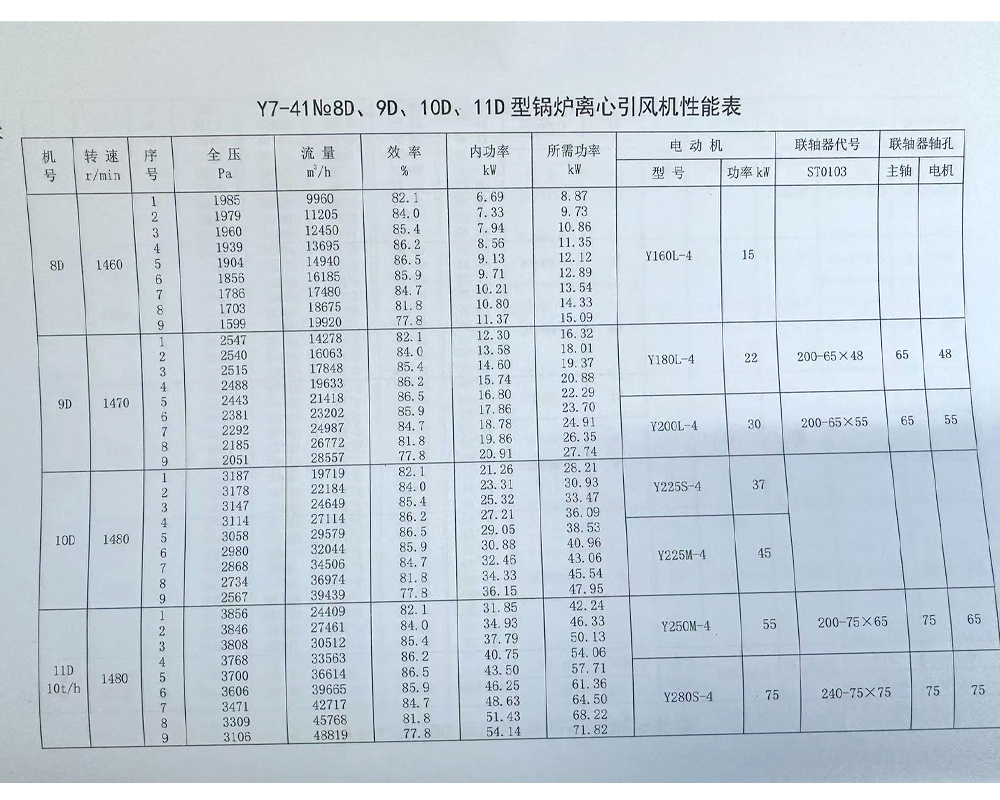

1. Both the fan and the induced draft fan are made with single suction; the fan has six models: N4.5, 5.6, 7.1, 8, 9, 12.5, and the induced draft fan has eight models: №4.5, 5.6, 7.1, 9, 10, 11, 11.2, 12.5.

2. Both the fan and the induced draft fan can be made in left-hand or right-hand rotation types. When viewed from the drive group end, if the impeller rotates clockwise, it is called right-hand rotation, indicated by 'right'. If it rotates counterclockwise, it is called left-hand rotation, indicated by 'left'.

3. The position of the fan outlet is indicated by the angle of the casing outlet. Both 'left' and 'right' can be made in three angles: 0°, 90°, and 180°.

4. The fan's drive modes are A type, C type, and D type.

Structure

The fan consists of an impeller, casing, inlet, drive group, and regulating door.

1. The impeller is made of backward inclined blades, welded between the arc conical cover and the flat disc. It has been dynamically and statically balanced and tested for overspeed operation, ensuring stable operation and a long service life.

2. The casing is welded from steel plates into a spiral shape. Models N8 and above are interchangeable for 'left' and 'right' rotation.

3. The drive group - the main shaft is made of high-quality steel and uses ball bearings. The №4.5~7.1C type drive uses an integrated two-part bearing housing, with No. 2 calcium-sodium based grease and self-cooling fan blades, featuring a simple structure.

4. The inlet - the converging-diverging inlet is made as a whole structure and is bolted to the inlet side of the casing.

5. The regulating door - regulates the fan flow. Fans N9 and below use a three-blade louver structure, which is flexible to close and has a simple structure. The №10 fan uses an 11-blade petal structure, axially mounted in front of the inlet, with a regulation range from 90° (fully closed) to 0° (fully open). The position of the regulating door handle, when viewed from the inlet direction, for the right-hand rotation fan, turning the handle counterclockwise goes from fully closed to fully open; for the left-hand rotation fan, turning the handle clockwise goes from fully closed to fully open.

To ensure the normal operation of the regulating door, lubrication must be guaranteed. Due to the high gas temperature of the induced draft fan, high-temperature (260°C) grease is used, which can still ensure lubrication during high-temperature operation.

Maintenance

1. Depending on various usage conditions, regularly clean the inside of the fan, especially the accumulation of dust and dirt on the blades, and prevent rust.

2. The grease in the bearing housing must be replaced if it deteriorates during fan operation. In addition to replacing it during repairs, under normal conditions, it should be replaced approximately every month. Remove the bearing side cover and the countersunk screws on the bearing housing, and inject No. 2 calcium-sodium based grease (suitable for temperatures below 100°C). The bearings should be cleaned once every six months.

3. Regularly check whether the bearing temperature is normal during operation; the bearing temperature should be below 100°C.

4. If any abnormal conditions are found during the fan's startup, shutdown, or operation, immediate maintenance should be performed.

5. To ensure personal safety, maintenance of the fan must be performed when it is stopped.

Noise

This series of fans is one of the lower noise fans among existing industrial boiler fans in the country.

When the fan leaves the factory, it has been tested, and its noise indicators meet the noise limit values for industrial fans set by the Ministry of Machinery Industry JB/T8690-1998. However, sometimes the fan may produce excessive noise during operation, mainly due to the following reasons:

1. Improper selection leading to the actual operating point being far from the highest efficiency operating point (beyond the 9 operating points in the performance table).

2. Severe fan vibration.

3. Misalignment of the shaft and rolling bearings, with the front and rear bearings not concentric.

4. Improper installation of pulleys or couplings.

5. Bearing wear and poor quality of grease, uncleanliness, etc.

6. For fans below 7.1, if low-noise bearings (309Z, 312Z, 314Z) are not used, users may find that the fan produces a lot of noise during operation, which can be eliminated based on the above reasons.

Faults and Causes

(1) Severe fan vibration:

1. Friction between the casing or inlet and the impeller;

2. Insufficient or unstable foundation stiffness.

3. Loose impeller rivets or deformed disc.

4. Loose fit between the impeller hub and the shaft.

5. Loose connecting bolts between the casing and the bracket, bearing housing and bracket, bearing housing and bearing cover, etc.

6. Poor installation of the fan outlet pipeline.

7. Dust and dirt accumulate on the blades, causing rotor imbalance;

8. Blade wear and impeller deformation;

9. The fan shaft and motor shaft are not aligned, the coupling is misaligned, or the pulley grooves are misaligned;

10. Shaft bending.

(II) Excessive bearing temperature rise:

1. The wind cooling disc nut is loose, causing self-cooling failure;

3. Poor quality of lubricating grease, deterioration or overfilling, containing impurities such as dust, sand, and dirt; 2. Severe vibration of the bearing housing;

4. The tightening force of the bearing housing cover bolts is too large or too small;

5. The shaft and rolling bearings are misaligned, with the front and rear bearings not concentric;

6. Rolling bearings are damaged;

7. Shaft bending.

(III) Excessive motor current and temperature:

1. The damper in the intake (outlet) pipe is not closed tightly when starting;

2. Flow exceeds the specified value or there is air leakage in the intake and exhaust ducts;

3. The gas temperature conveyed by the fan is too low, contains viscous substances, or has excessive dust content.

4. The spindle speed exceeds the specified value;

5. The input voltage of the motor is too low or the power supply is single-phase cut off;

6. Due to the misalignment of the two bearings, the coupling and pulley are improperly installed, causing large no-load losses;

7. The direction of the matched impeller is incorrect;

8. Affected by severe vibration of the bearing housing.

(IV) Belt slipping down:

The positions of the two or three V-belt pulleys are not on the same centerline.

(V) Belt too loose:

Belt wear and elongation cause the belt to be too loose, and the center distance of the two or three V-belt pulleys does not match the belt length, so the distance between the motor and the spindle on the motor slide rail should be adjusted.

Ordering Notes

When ordering, please specify the fan's model number, speed, air volume, air pressure, working temperature, outlet angle, rotation direction, motor model, power, speed, etc.

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Inquiry Message

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products