Hebei Zhengtian Fan Manufacturing Co., Ltd.

Contact Us

E-mail:

youtian@hbztfj.com

WhatsApp:

Add:

Renqiu City, Cangzhou City, Hebei province, discuss Bao township Shoulian village east Yi road east

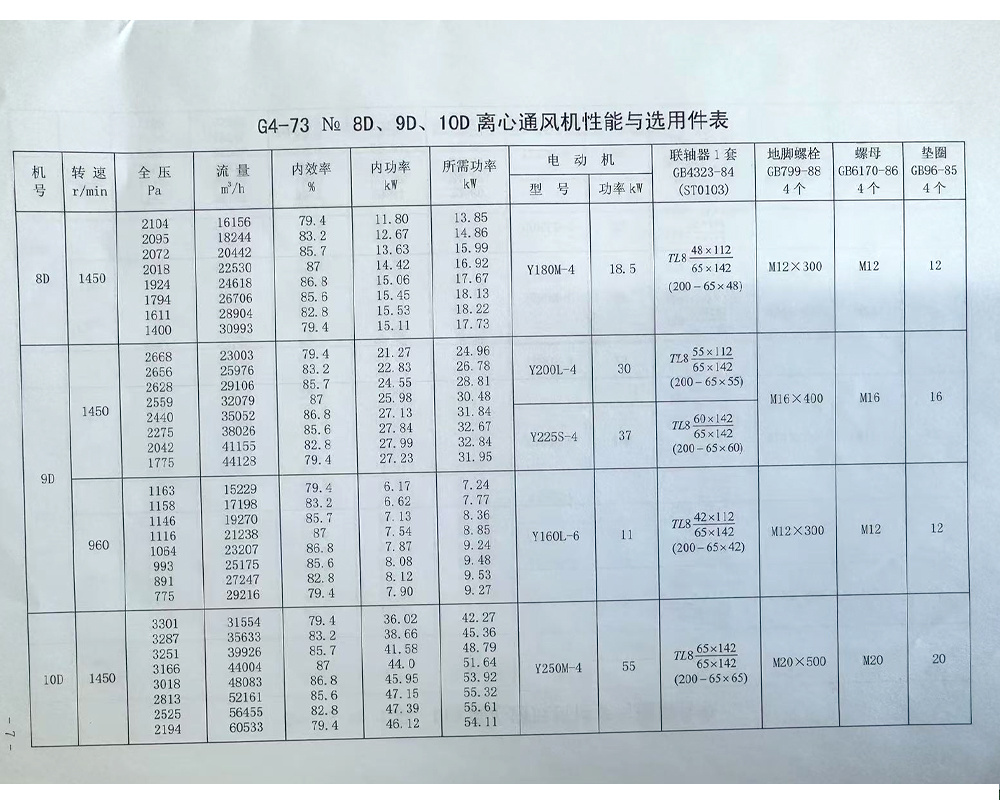

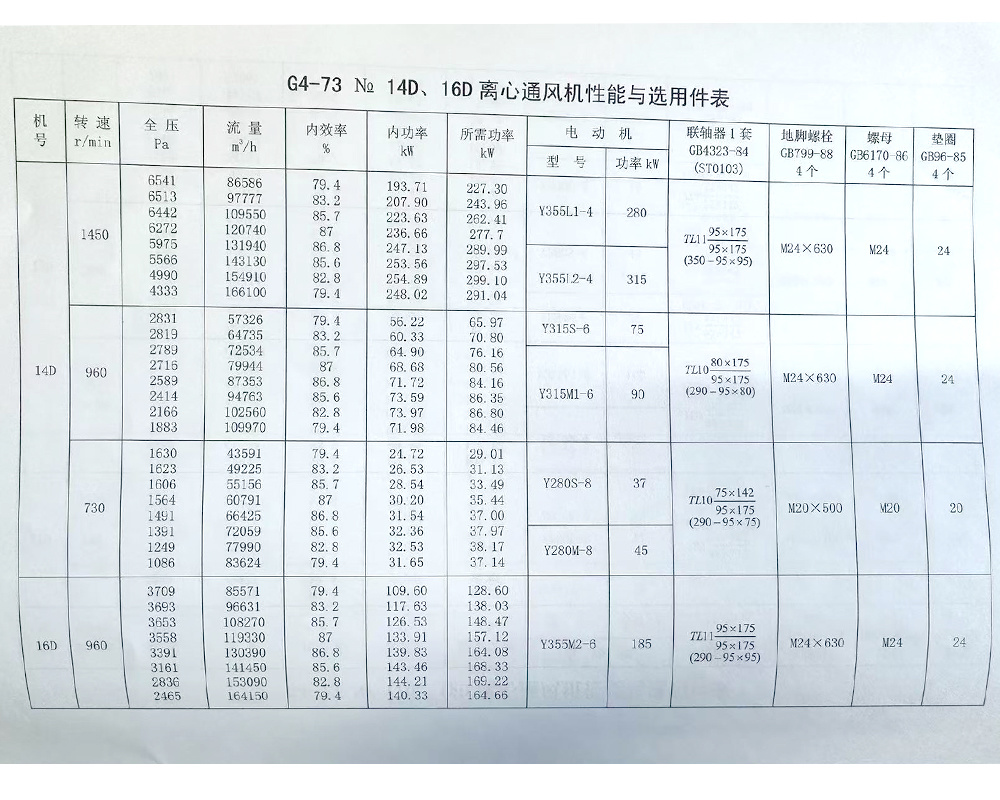

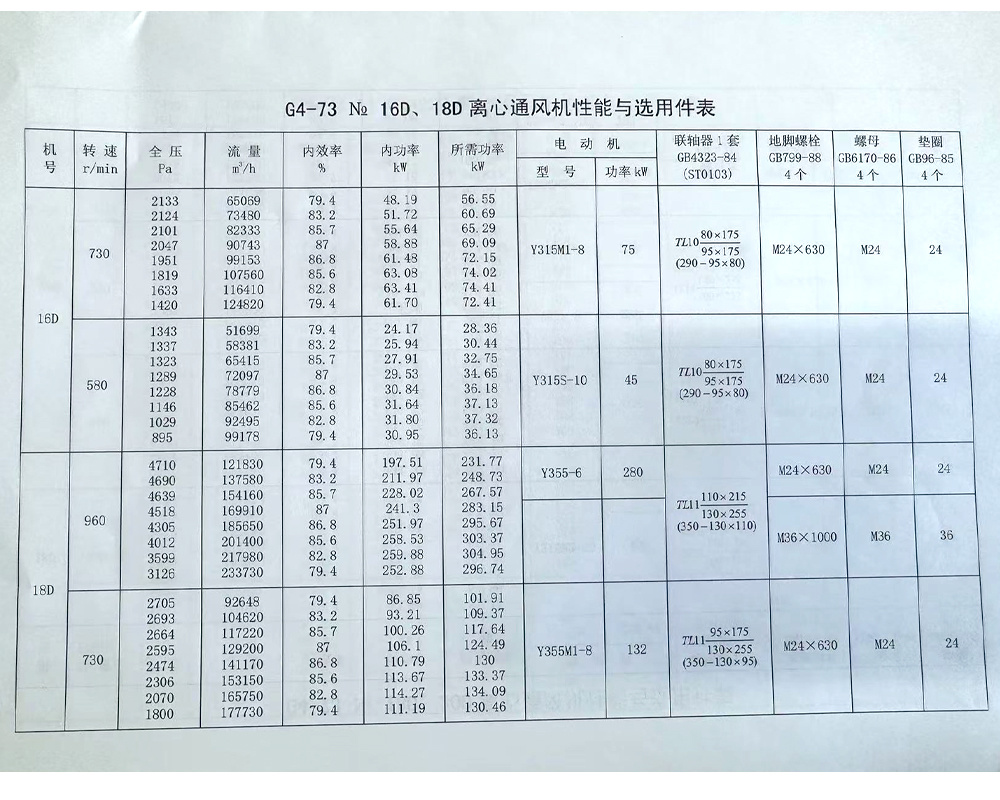

4-73

keyword:

- Description

-

Purpose

The G4-73 and Y4-73 type boilers' induced draft and forced draft fans are mainly suitable for the induced draft and forced draft fan systems of steam boilers ranging from 2 to 670t/h in thermal power plants. In the absence of other special requirements, G4-73 can also be used for mine ventilation and general ventilation.

The medium conveyed by the fan is air, and the temperature must not exceed 80℃; the medium conveyed by the induced draft fan is flue gas, and the maximum temperature must not exceed 250℃.

A dust removal device must be installed before the induced draft fan to minimize the dust content of the flue gas entering the fan. According to the general usage conditions of power plants, the efficiency of the dust collector must not be less than 85%.

Type

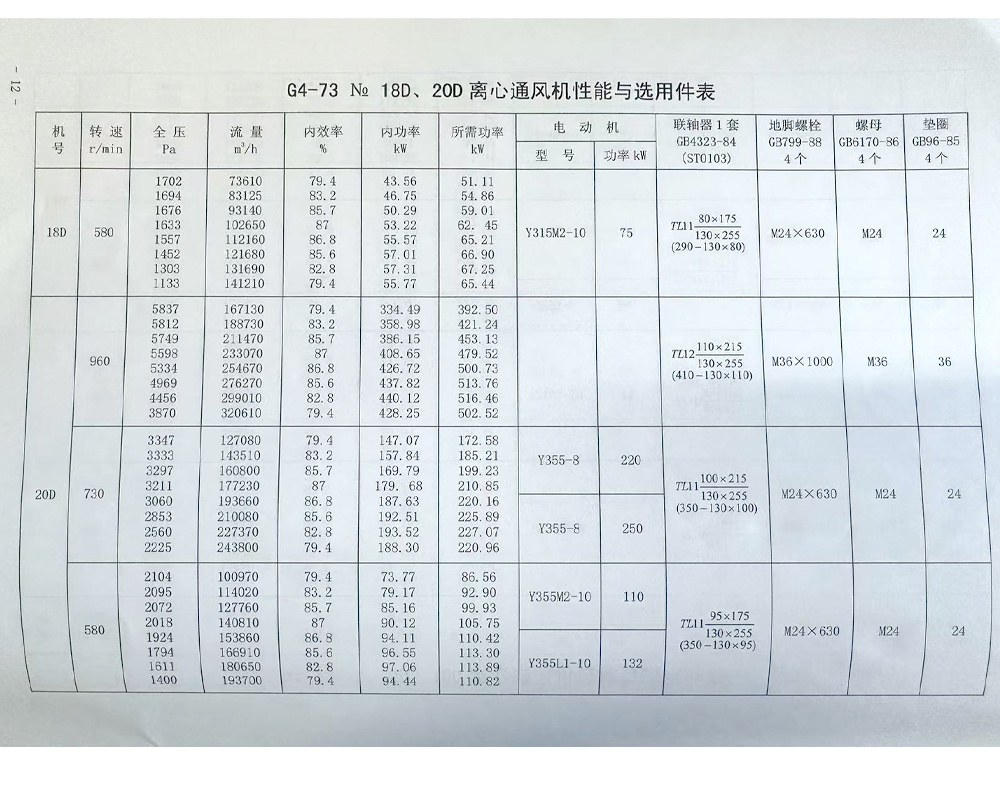

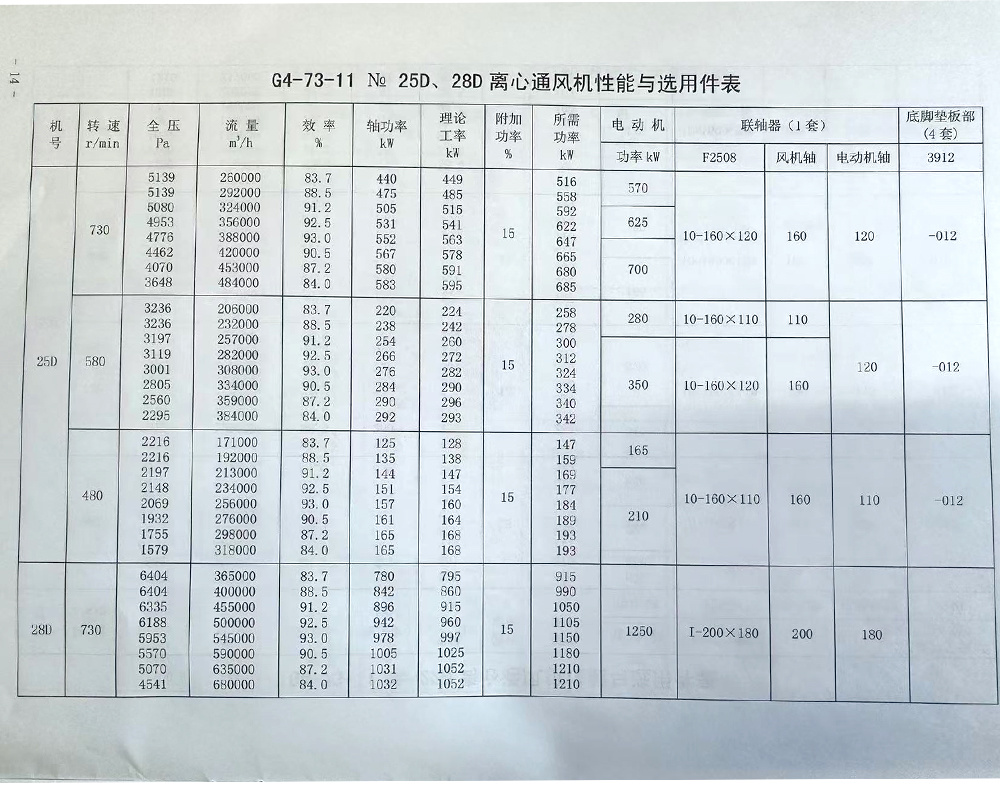

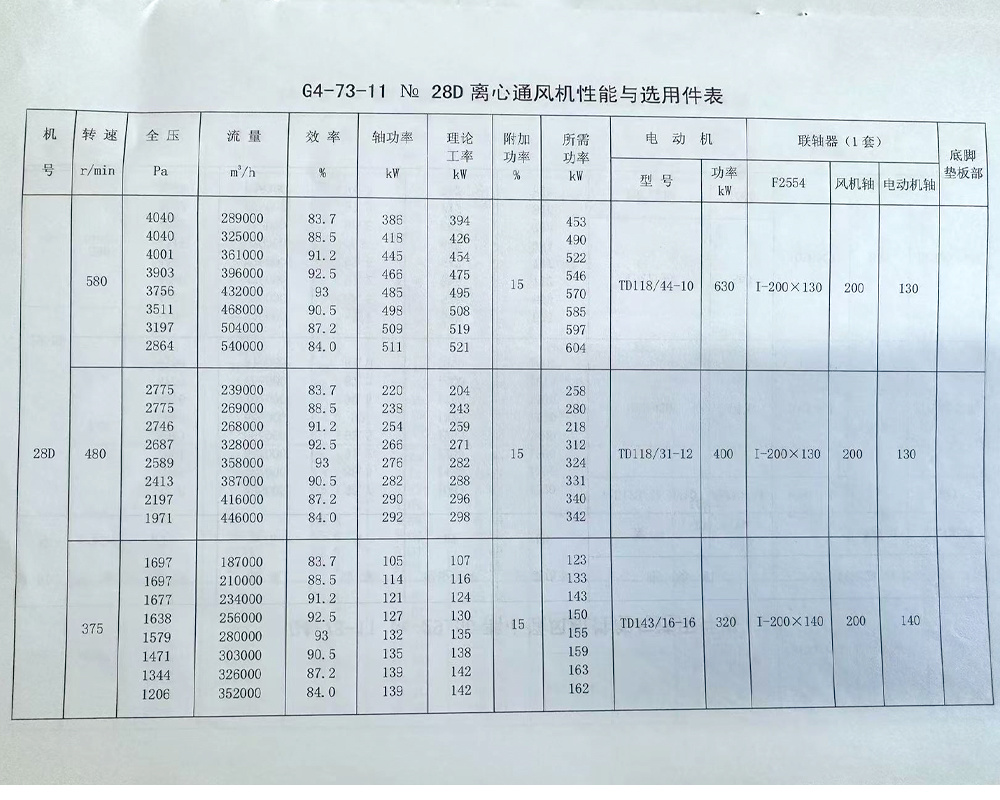

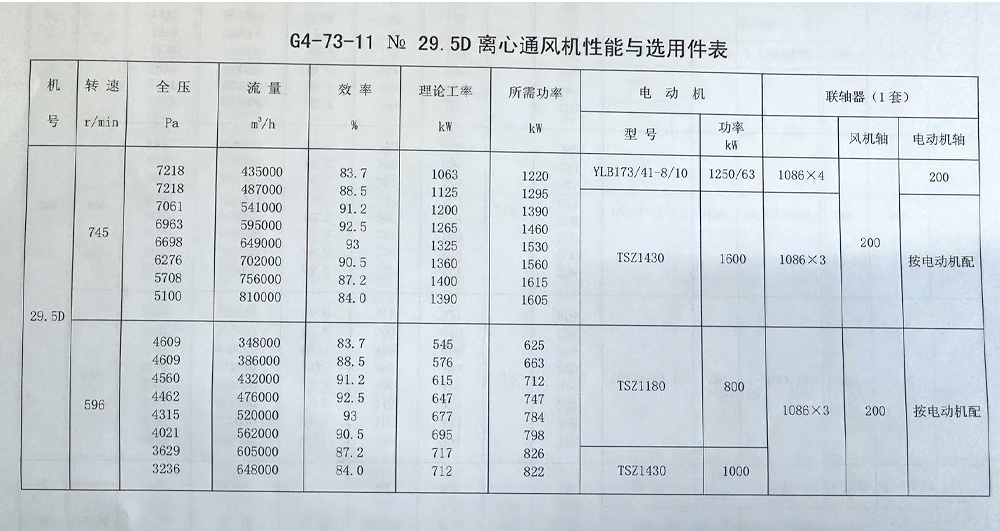

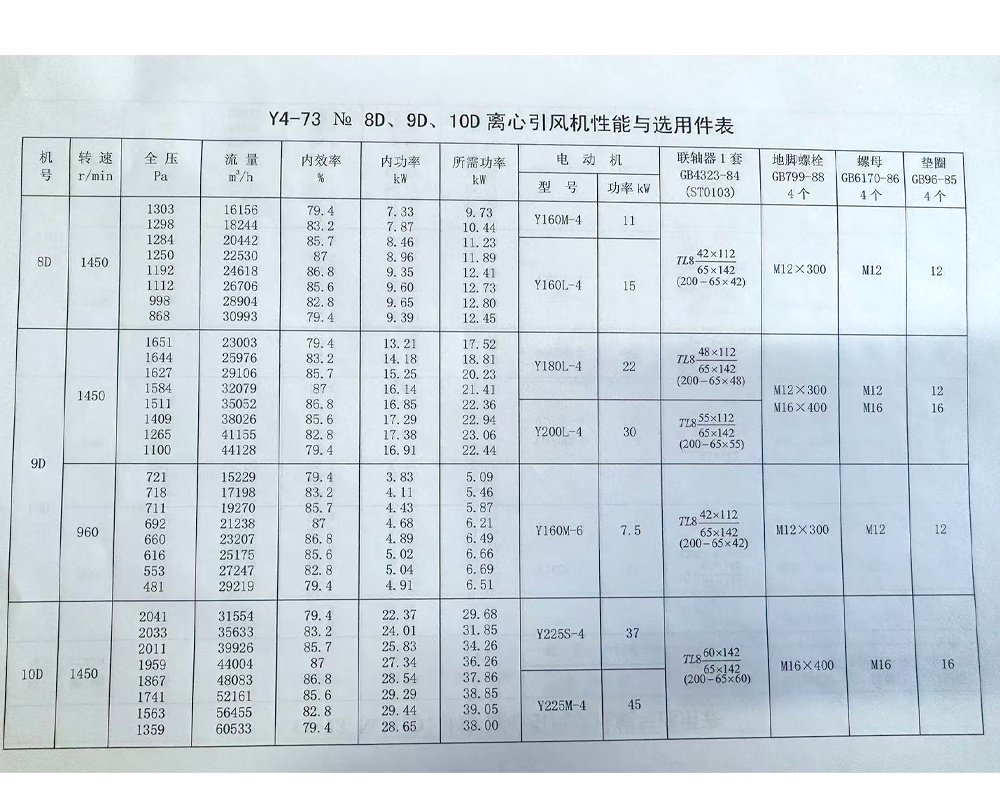

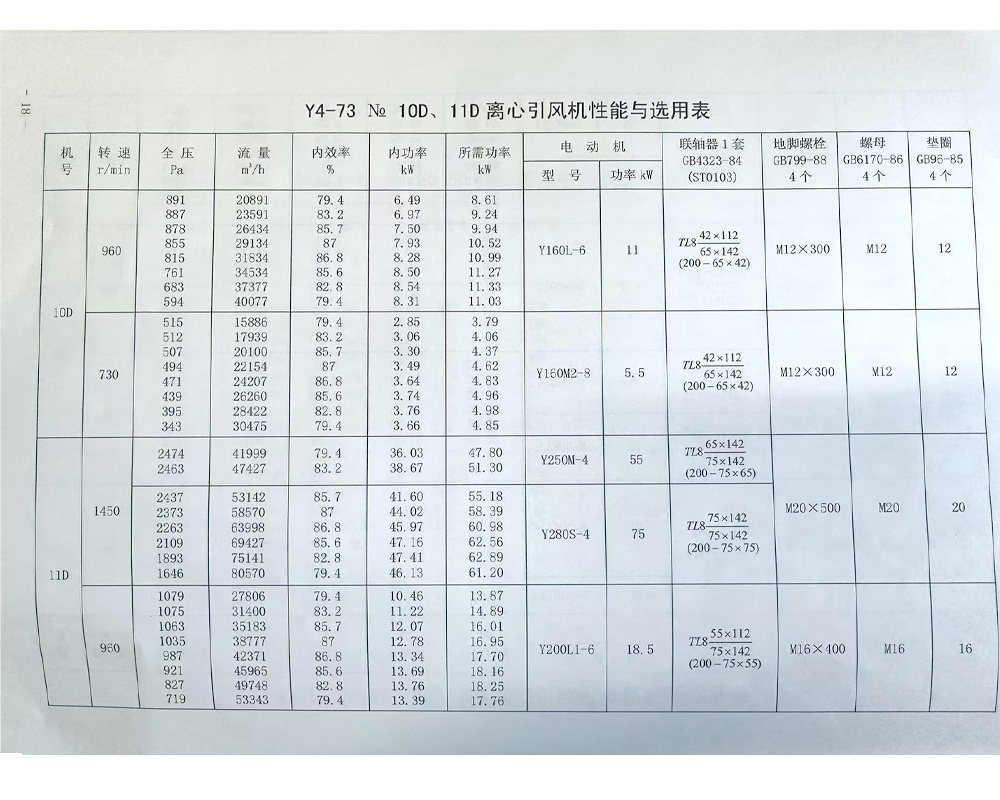

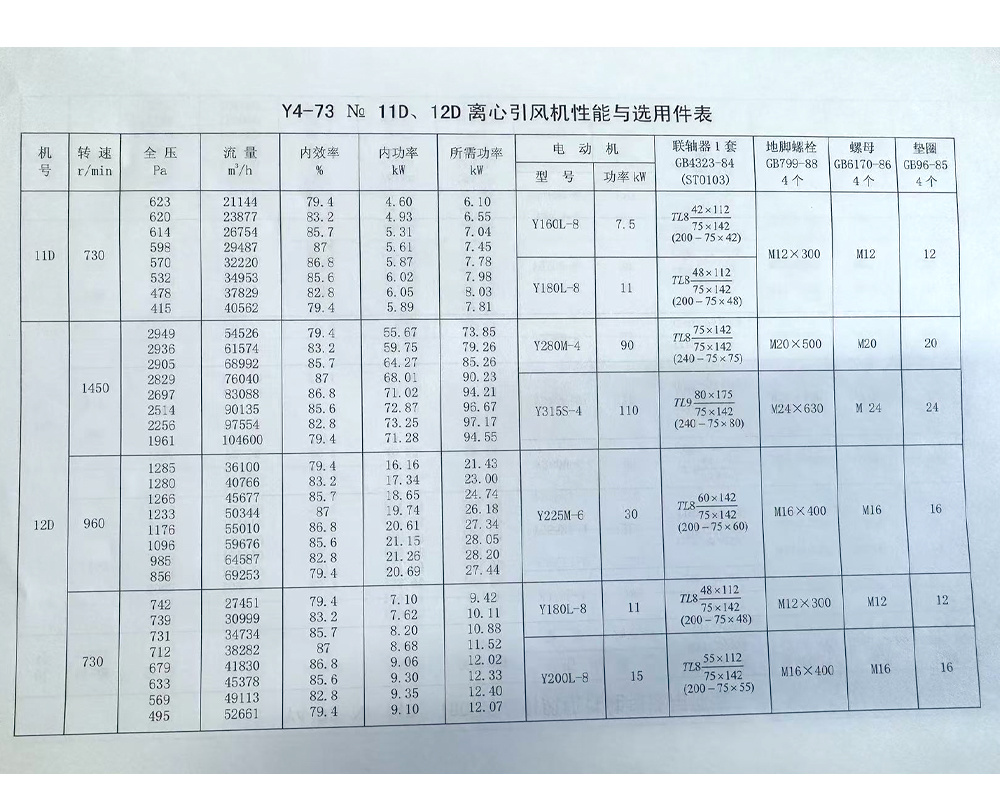

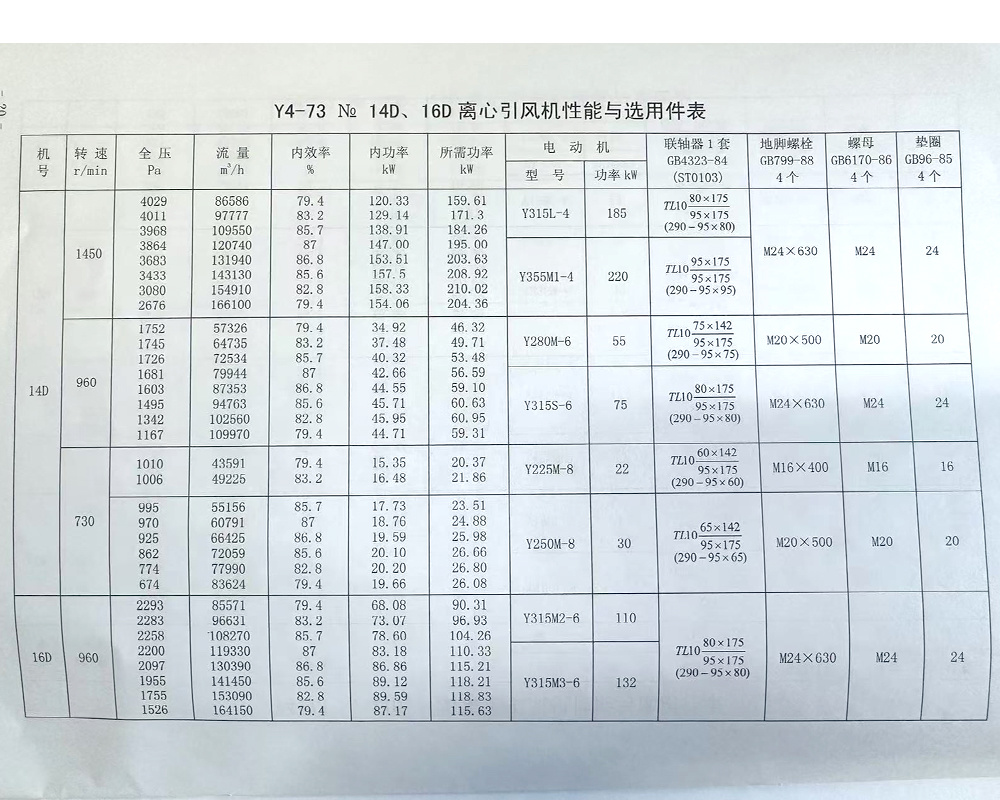

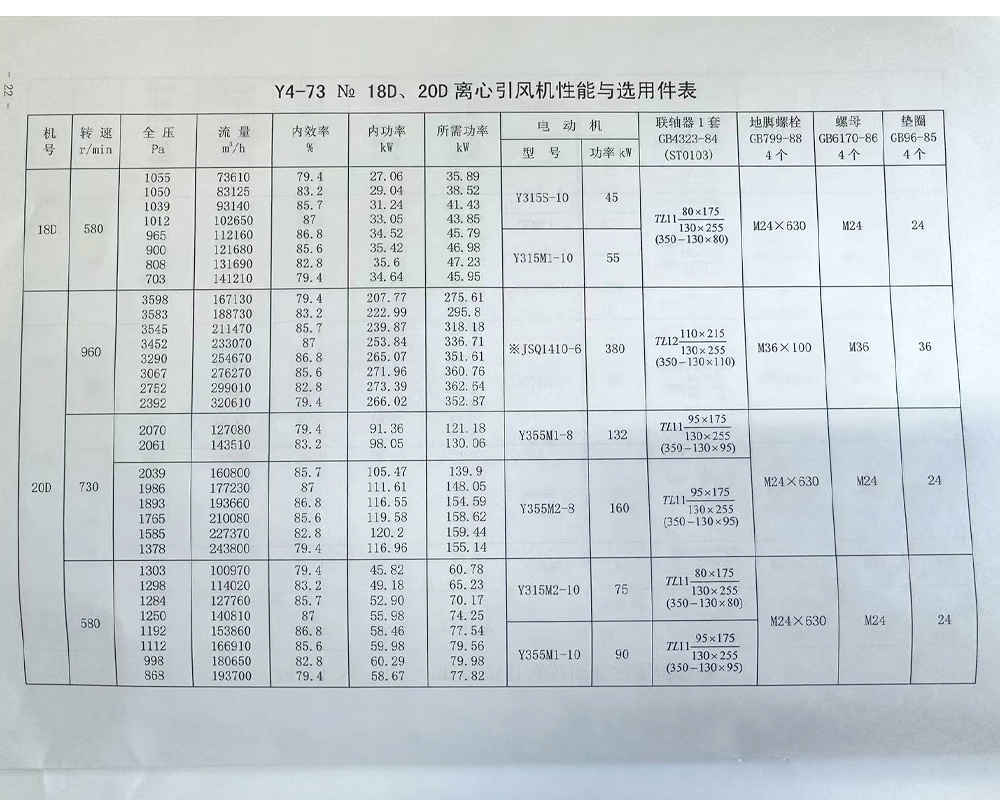

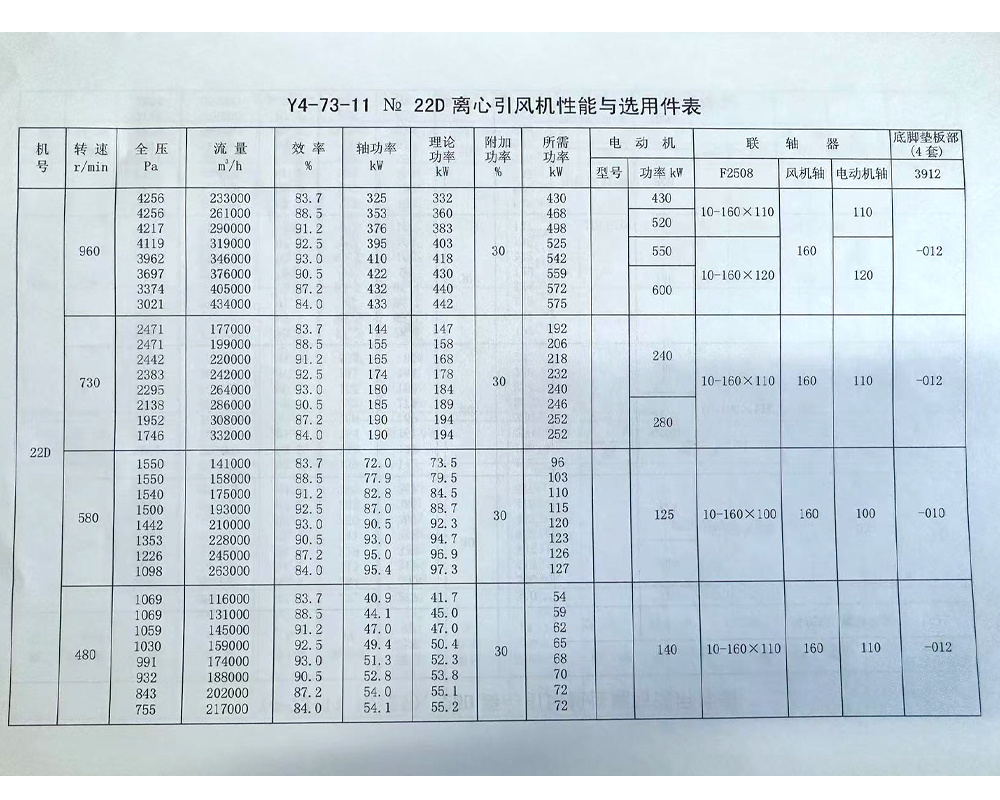

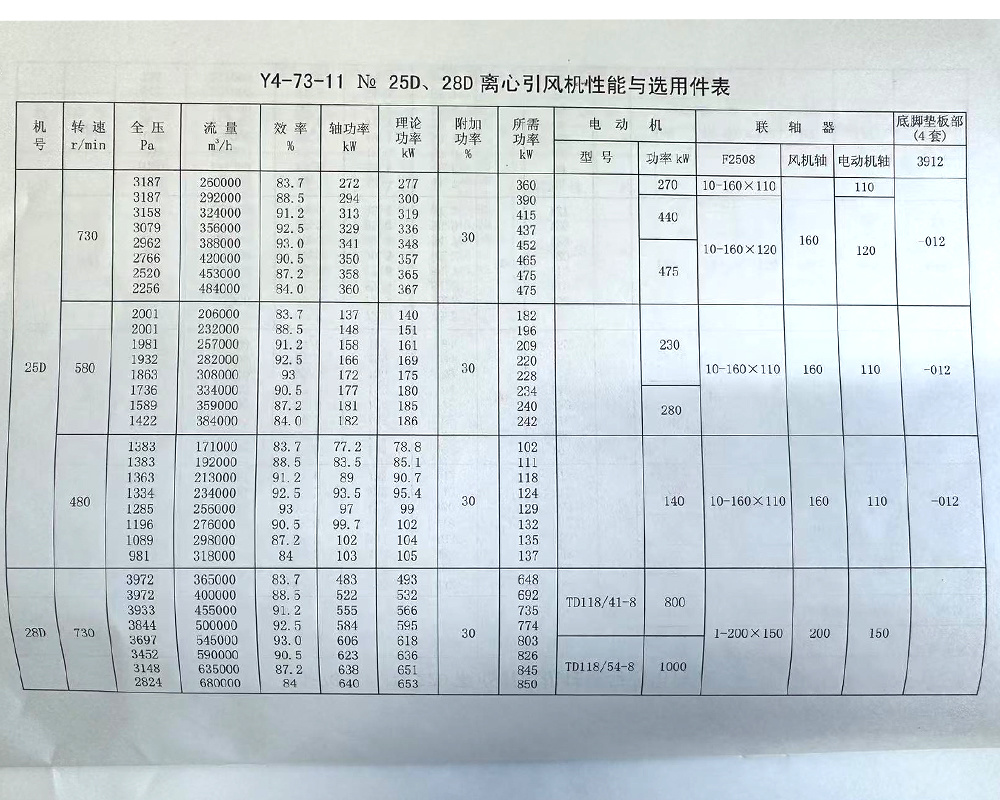

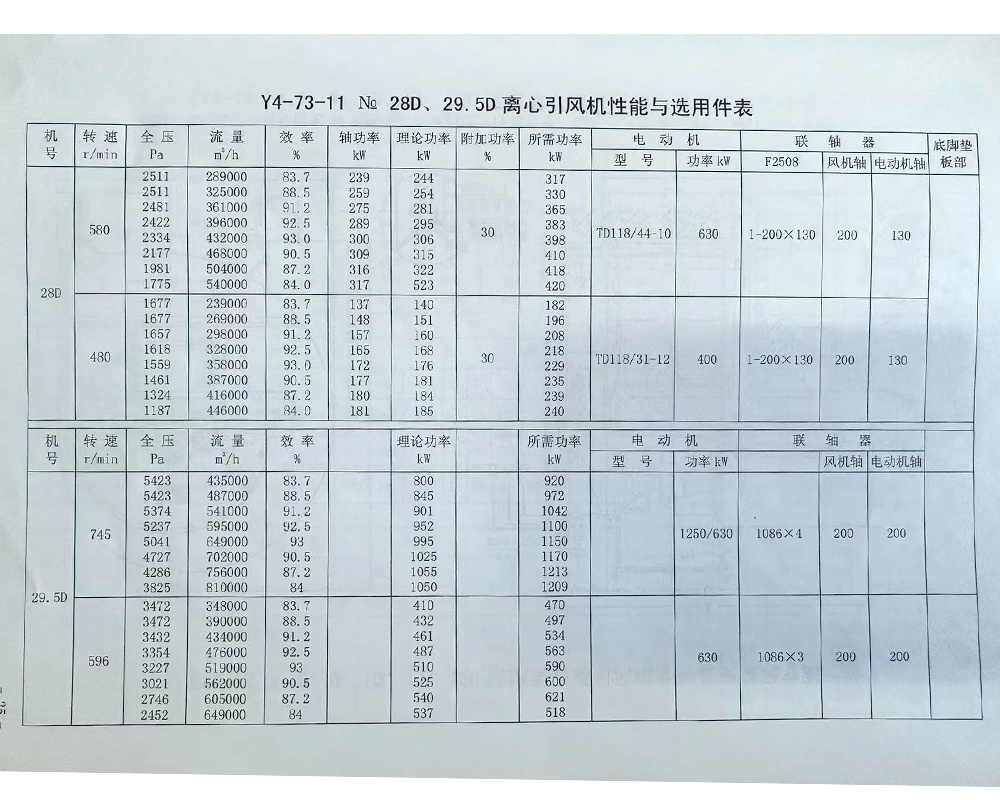

1. Both the forced draft fan and the induced draft fan are made with single suction, with a total of 13 models ranging from N8 to 29.5.

2. When viewed from the motor end, the impeller rotates clockwise is called a right-handed fan, indicated by "right"; conversely, it is a left-handed fan, indicated by "left".

3. The position of the fan's outlet is indicated by the angle of the outlet of the casing.

4. The fan's drive mode is of type D, using elastic couplings for connection.

Fan Maintenance

(1) Fan Maintenance Work System

1. The fan must be operated by designated personnel and maintained by designated personnel.

2. The fan must not operate with faults.

3. Regularly remove dust from inside the fan, especially impurities such as dust and dirt on the impeller, to prevent rust and imbalance.

4. Maintenance of the fan must emphasize first cutting off the power before stopping.

(2) Precautions During Normal Operation of the Fan

1. If excessive flow is detected, or if a smaller flow is needed in a short time, the adjustment door can be used for regulation.

2. Regularly check the sensitivity of the thermometer and oil gauge.

3. Apart from changing the lubricating oil after each disassembly, under normal circumstances, change the lubricating oil every 3 to 6 months.

(3) Main Failures and Causes of the Fan

1. Severe vibration of the bearing box

① The fan shaft and motor shaft are misaligned, and the coupling is installed incorrectly;

② The casing or inlet rubs against the impeller;

③ The foundation is not rigid enough;

④ The impeller rivets are loose or the impeller is deformed;

⑤ The impeller shaft disc is loose with the shaft, or the coupling bolts are loose;

⑥ The connecting bolts between the casing and the bracket, bearing box and bracket, bearing box cover and seat are loose;

⑦ Poor installation of the fan's inlet and outlet pipelines;

⑧ Rotor imbalance;

⑨ Wear of the induced draft fan blades.

2. Excessive temperature rise of the bearing

① Severe vibration of the bearing box;

② Poor quality, deterioration, or excessive dust, sand, dirt, and other impurities in the lubricating grease;

③ The tightening force of the bolts connecting the bearing box cover and seat is too large or too small;

④ The shaft and rolling bearings are misaligned, and the front and rear bearings are not concentric;

⑤ Rolling bearings are damaged.

3. Excessive motor current or temperature rise

① The intake duct damper or throttle valve is not closed tightly when starting:

② Flow exceeds the specified value;

③ The density of the gas conveyed by the fan is too high or contains viscous substances;

④ The input voltage of the motor is too low or the power supply is single-phase cut off;

⑤ The coupling connection is incorrect, the rubber ring is too tight or the gap is not engaged;

⑥ Affected by severe vibration of the bearing box.

(4) Contact the manufacturer during installation and repair

Ordering Instructions

When ordering, it is necessary to specify in writing the fan's model number, speed, air volume, air pressure, outlet angle, rotation direction, and the model specifications of the motor.

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Inquiry Message

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products