Hebei Zhengtian Fan Manufacturing Co., Ltd.

Contact Us

E-mail:

youtian@hbztfj.com

WhatsApp:

Add:

Renqiu City, Cangzhou City, Hebei province, discuss Bao township Shoulian village east Yi road east

Boiler centrifugal induced draft fan

keyword:

- Description

-

Purpose and Features

The G, Y6-41 type boiler centrifugal fan and induced draft fan are designed for industrial boilers with a capacity of 0.5t/h to 10t/h that can burn various types of coal and are equipped with dust removal devices. They are a new series of low-noise fans with a total pressure efficiency greater than 80%. Any fan with equivalent intake conditions and performance can be selected.

The G, Y6-41 series centrifugal fans are the upgraded products of boiler induced draft fans.

The design methods used for the G, Y6-41 series fans include: selecting the appropriate fan type, reasonable fan work, optimizing flow patterns, organizing air sources rationally, carefully designing blade shapes, increasing the gap between the wind tongue, appropriately reducing fan speed, improving the design of the volute to purify the inflow and minimize secondary flow losses, etc. The finite difference method is used to calculate the inlet and impeller cover profiles, and the smooth and uniform airflow at the impeller inlet is used as the optimization criterion for the inlet optimization design. Combined with the existing optimization design methods for fan impellers and volutes, a comprehensive optimization design program integrating the impeller, volute, and inlet is developed, resulting in aerodynamic characteristic curves. Practice has proven that it can ensure wind pressure and air volume while also ensuring high efficiency and low specific noise.

Structure

The induced draft fans produced by our factory consist of components such as the impeller, inlet, and casing. The bearing box has an integrated structure with oil lubrication and cooling, cantilever support, and the pulley and coupling are located outside the bearing.

The induced draft fan should be equipped with an adjustment door. If users need it, they can place a separate order for the adjustment door from our factory.

The fan impeller adopts backward-curved arc blades, and the wheel cover is a conical curved surface combined with a streamlined inlet, all made using mold stamping technology, giving the fan advantages such as good aerodynamic performance, resistance to dust accumulation, low noise, precise geometric dimensions, and stable quality.

Faults and Causes

1. Severe fan vibration

(1) The fan shaft is not parallel to the motor shaft, and the pulleys are misaligned.

(2) The casing or inlet is rubbing against the impeller.

(3) The foundation is not rigid enough or not stable.

(4) The impeller rivets are loose or the impeller is deformed.

(5) The impeller hub hole is loose in its fit with the shaft.

(6) The blades have dust, dirt, wear, corrosion, or the shaft is bent, causing rotor imbalance.

(7) Poor installation of the inlet and outlet pipelines of the fan, causing resonance.

(8) Loose connecting bolts between the casing and the bracket, bearing seat and bracket, bearing seat and bearing cover.2. Excessive temperature rise of the bearings

(1) Severe vibration of the bearing seat.

(2) Incorrect viscosity of the lubricant, deterioration, or contamination, insufficient or excessive filling of the lubricant. (3) Damage to rolling bearings or bent shafts, and the fit tolerance of the inner or outer rings of the bearings is too loose or too tight.3. Excessive motor current or temperature rise

(1) The inlet pipe is not properly closed when starting.

(2) The gas being conveyed contains viscous substances.

(3) The spindle speed exceeds the rated value.

(4) Severe vibration of the bearing box.

(5) The input voltage of the motor is too low or there is a phase loss in the current.4. Belt jumping or slipping:

Belt wear or elongation makes it too loose, or the grooves of the two pulleys are not aligned on the same centerline.

Ordering Instructions

1. When placing an order, please specify: fan model, wind pressure, air volume, outlet position, rotation direction, quantity, adjustment door options, and any other special requirements. For the supply list of a single product, please refer to the table below. Special and custom fans can be discussed directly with our factory.

2. The matching induced draft and forced draft fans for the boiler can be selected according to the table below.

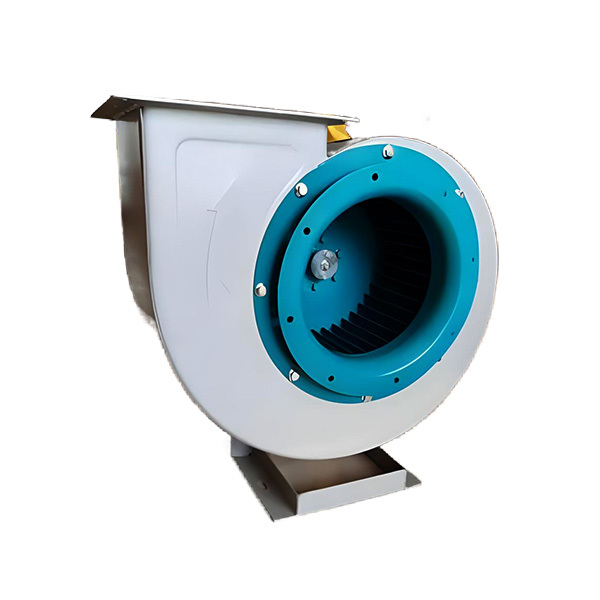

Boiler Output (t/h) Fan Model Induced Draft Fan Forced Draft Fan 0.5 G6-41-11 NO2.5A Y6-41-11 NO3.55C 1.0 3.3A 4.5C 2.0 5.4A 5.4C 4.0 6.4A 7.1C 6.0 7.1A 9C, 10C 10 8.5A 11.2D G, Y6-41 series fan dimensionless performance curves

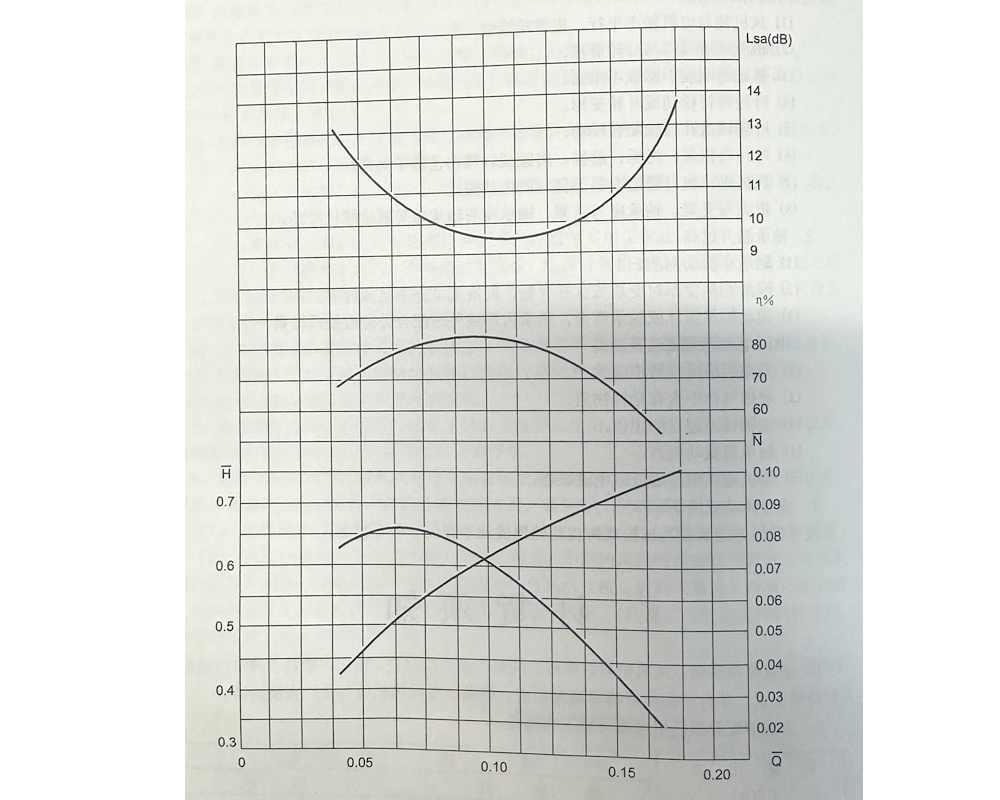

Motor slide rail dimension diagram

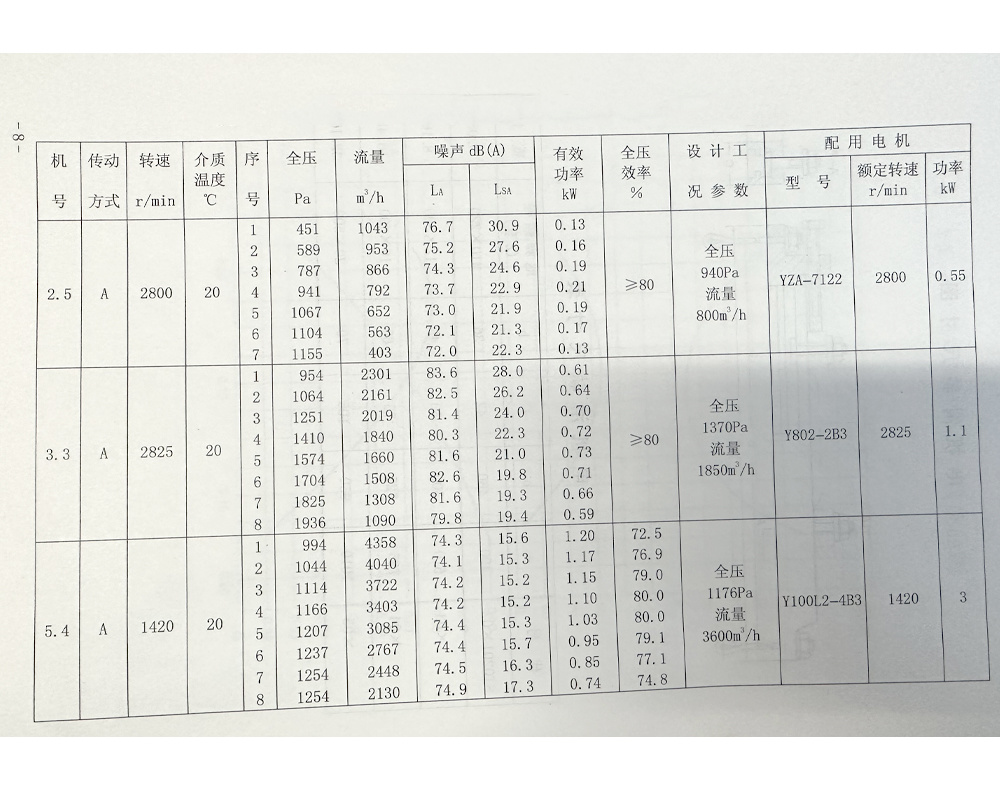

G6-41-11NO2.5A, 3.A, 5.4A boiler centrifugal fan performance table

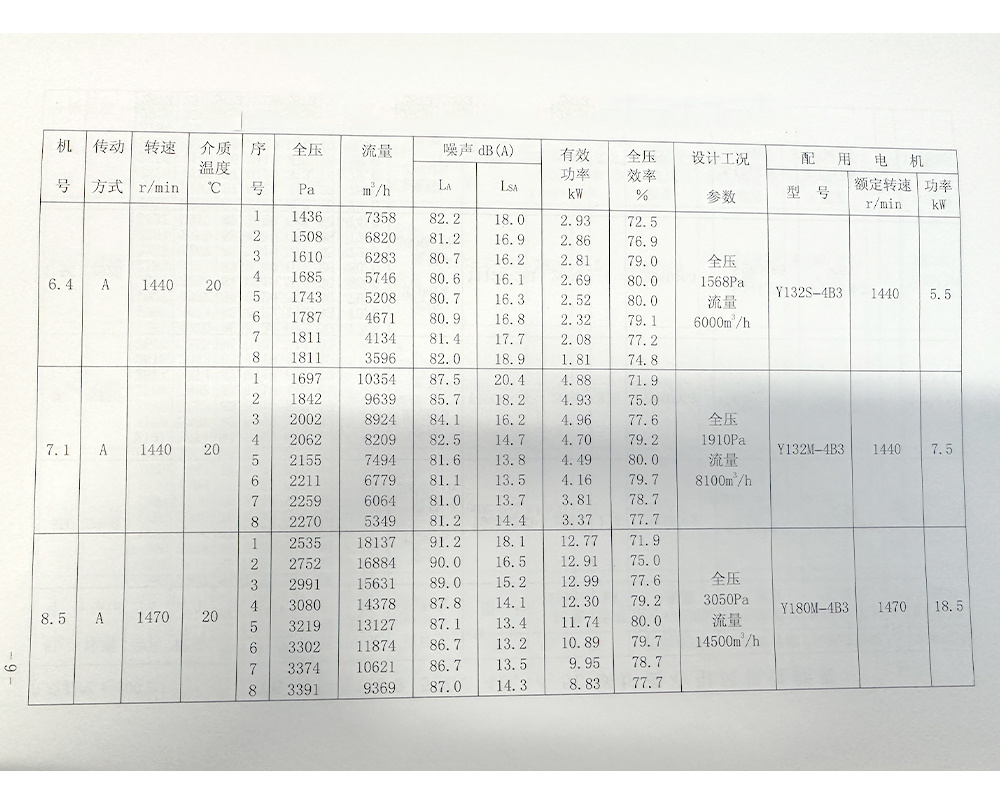

G6-41-11NO26.4A, 7.1A and 8.5A boiler centrifugal fan performance table

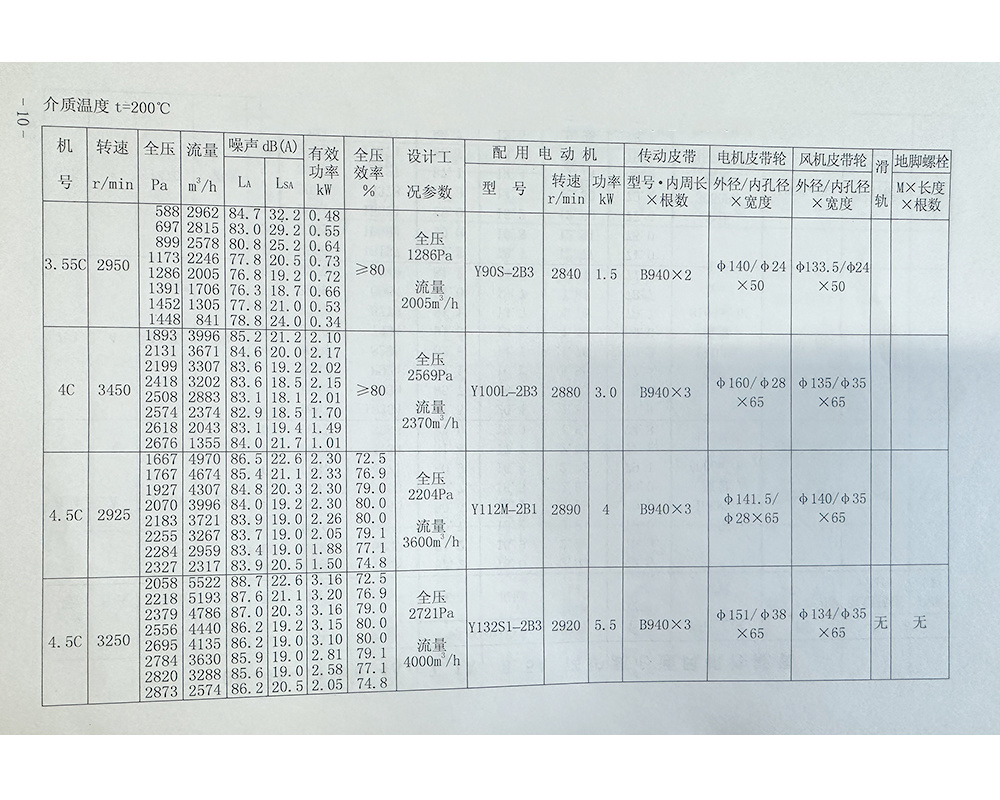

Y6-41-11NO3.55C, 40 and 4.5C boiler centrifugal fan performance table

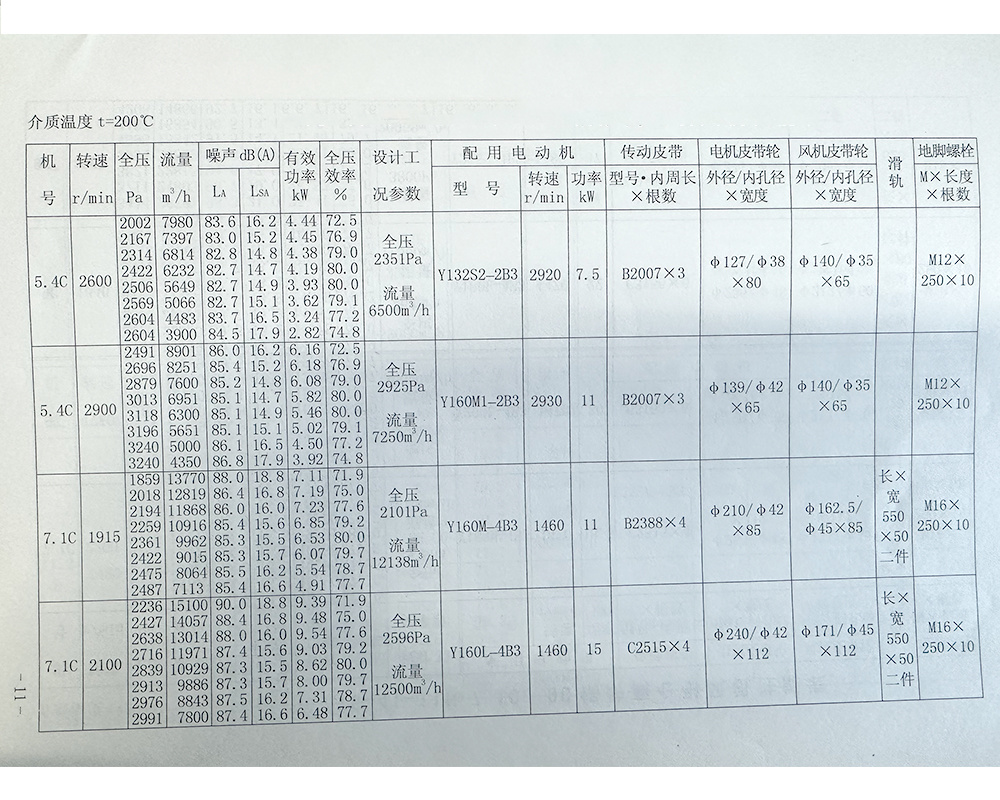

Y6-41-11 NO5.40 and 7.10 boiler centrifugal fan performance table

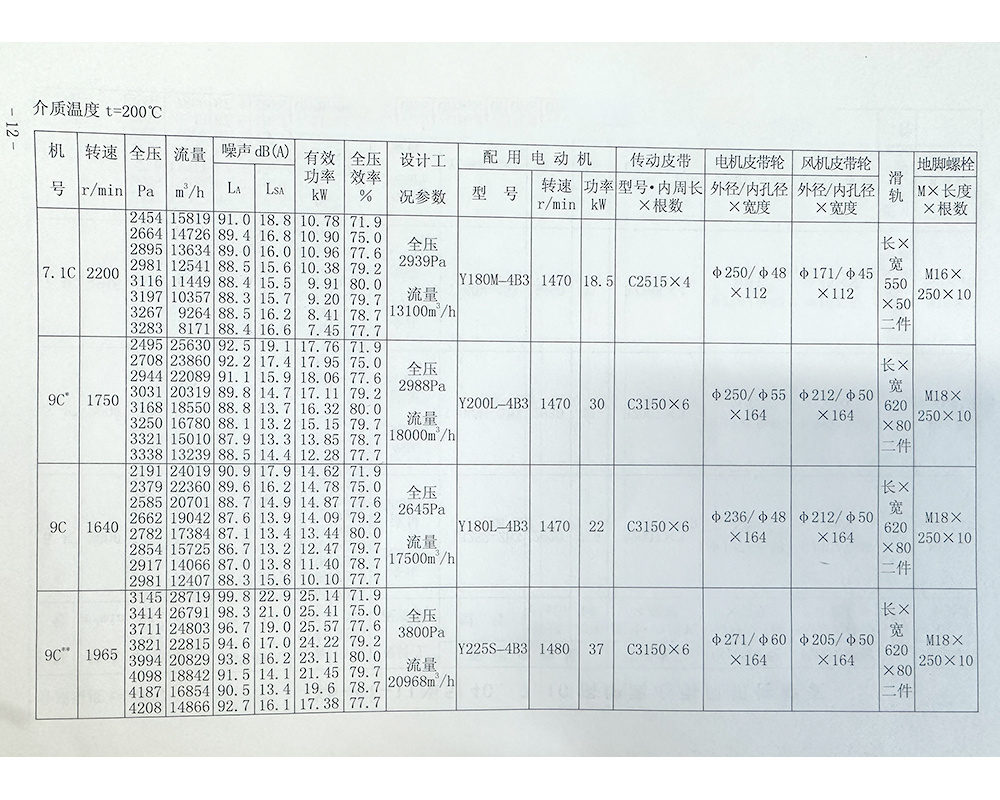

Y6-41-11NO7.10 and 9C boiler centrifugal fan performance table

Y6-41-11NO210C.11.2D boiler centrifugal fan performance table

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Inquiry Message

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products