Hebei Zhengtian Fan Manufacturing Co., Ltd.

Contact Us

E-mail:

youtian@hbztfj.com

WhatsApp:

Add:

Renqiu City, Cangzhou City, Hebei province, discuss Bao township Shoulian village east Yi road east

High-pressure centrifugal fan 9-26

keyword:

- Description

-

Usage

9-19 and 9-26 high-pressure centrifugal fans are generally used for forging furnaces and high-pressure forced ventilation. They can also be widely used for conveying materials, air, and gases that are non-corrosive, non-self-igniting, non-explosive, non-volatile, and do not contain viscous substances. The medium temperature generally does not exceed 50℃ (maximum not exceeding 80℃), and the content of dust and hard particles in the medium is not more than 150mg/m³ 3。

Type

This fan is a single-suction type, and there are 13 models in total: №4, 4.5, 5, 5.6, 6.3, 7.1, 8, 9, 10, 11.2, 12.5, 14, and 16.

This fan is usually made in two types: right-rotating and left-rotating. Viewed from the motor end, the impeller rotating clockwise is called a right-rotating fan, indicated by "right", and the impeller rotating counterclockwise is called a left-rotating fan, indicated by "left".

The outlet position of the fan is indicated by the outlet angle of the casing. Both "left" and "right" can be made into six angles: 0°, 45°, 90°, 135°, 180°, and 225°.

The fan's transmission method is divided into three types: A (N4~6.3), D, and C (7.1~16).

If the above model numbers, rotation direction, outlet angle, and transmission method do not meet your needs, we have the ability to custom-design to your satisfaction.

Structure

N4~6.3 mainly consists of an impeller, casing, inlet, and bracket; N7.1~16 mainly consists of an impeller, casing, inlet, and transmission assembly.

Impeller -- The 9-19 type fan has 12 blades, and the 9-26 type fan has 16 blades, both of which are forward-curved. The maximum peripheral speed of the impeller pressure edge shall not exceed 140m/s. After the impeller is formed, it undergoes static and dynamic balance correction and overspeed operation experiments, so the operation is stable and reliable.

Casing -- Welded from ordinary steel plates into a volute shape.

Inlet -- Made into a convergent streamlined integral structure, fixed to the front cover with bolts.

Transmission assembly -- Consists of a main shaft, bearing box, and coupling. The main shaft is made of high-quality steel, the bearing box has an integral structure, uses rolling bearings, and is lubricated with bearing grease.Maintenance

① The fan and its system are not allowed to operate with faults.

② The fan should be kept and used by a designated person.

③ Regularly clean the dust, dirt, and other impurities inside the fan to prevent rust.

④ Fan maintenance must be carried out after power is cut off, and a designated person should monitor the main switch after power is cut off.

⑤ During fan maintenance and trial operation, children, irrelevant personnel, and people with mobility impairments are prohibited from watching.

⑥ During the trial operation of the fan, no one is allowed to stand within 10 meters of the fan inlet and outlet.

⑦ Before and after repairing the fan, the tools and other supplies should be checked to prevent them from being left in the fan and pipeline.

⑧ Except for lubricating oil, which should be replaced after each overhaul, lubricating oil should be replaced according to the actual situation under normal circumstances.Faults and Causes

1. Severe fan vibration

① The fan shaft and motor shaft are not concentric, and the pulley groove is misaligned;

② Friction between the casing and the impeller or between the inlet and the impeller;

③ Insufficient or unstable foundation rigidity;

④ Loose impeller rivets or impeller deformation;

⑤ Loose fit between the impeller shaft hole and the shaft;

⑥ Loose connecting bolts between the casing, bearing housing, and bracket;

⑦ Poor installation of the fan inlet and outlet pipes, leading to resonance;

⑧ Dust, dirt, blade wear, impeller deformation, shaft bending, etc., causing rotor imbalance.2. Bearing temperature is too high

① Severe vibration of the bearing box;

② Poor quality, deteriorated lubricant, or containing dust, sand, dirt, etc., or insufficient filling;

③ The tightening force of the connecting bolts between the bearing box cover and seat is too large or too small;

④ The main shaft and rolling bearing are installed obliquely, and the front and rear bearings are not concentric;

⑤ Rolling bearing damage or main shaft bending.3. Motor current is too large or temperature rise is too high

① Inlet and outlet pipe valves are not closed during startup;

② Low motor input voltage or single-phase power failure;

③ Affected by severe vibration of the bearing box;

④ Main shaft speed exceeds the rated value;

⑤ The input gas contains viscous substances;

⑥ The ambient temperature is too low, and the proportion is too large.Scope of Supply for Single-Unit Products

1 fan, 1 matching motor, 1 set of foundation bolts (N4~6.3, 4 sets; №7.1 and above, 8 sets), 1 coupling (Na7.1~16).

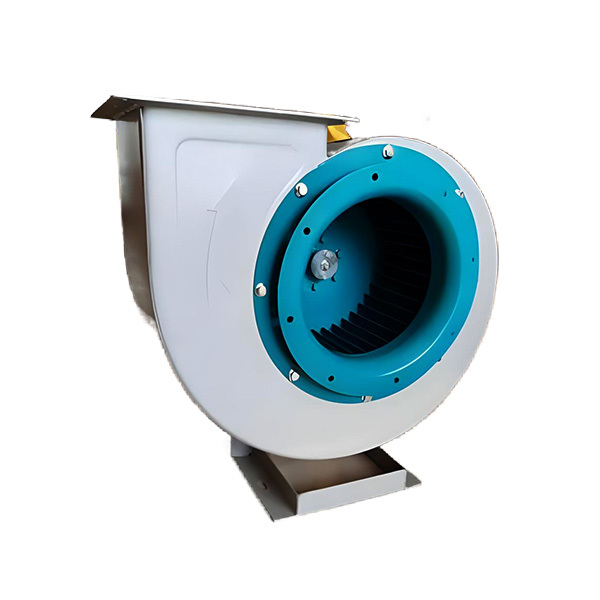

9-19 N4A, 4.5A, 5A and 5.6A High-Pressure Centrifugal Fan Performance and Selection Parts Table

9-19 NO6.3A, 7.1D, 8D High-Pressure Centrifugal Fan Performance and Selection Parts Table

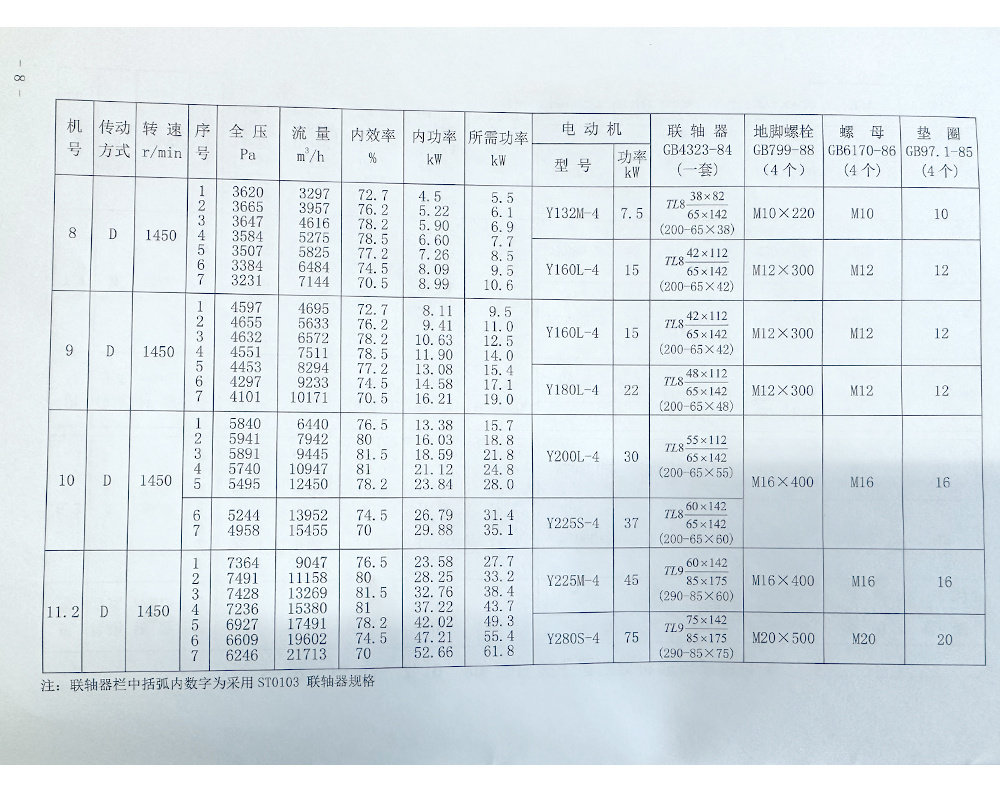

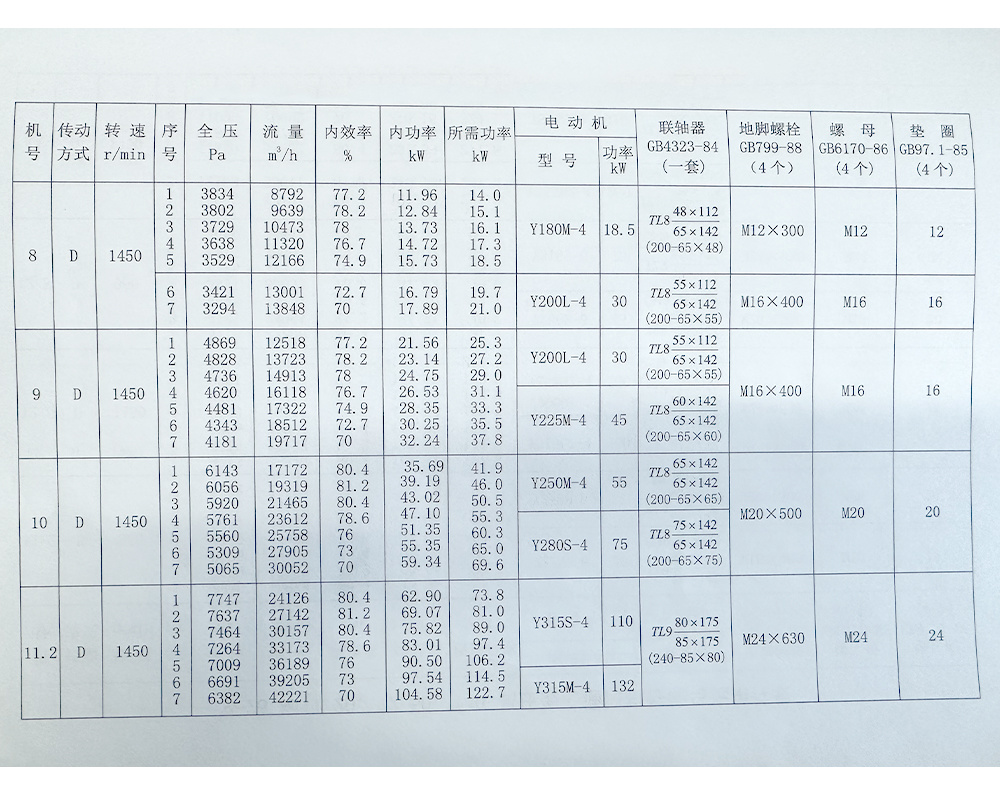

Performance and Selection Table for 9-19 N8D, 9D, 10D, 11.2D High-Pressure Centrifugal Fans

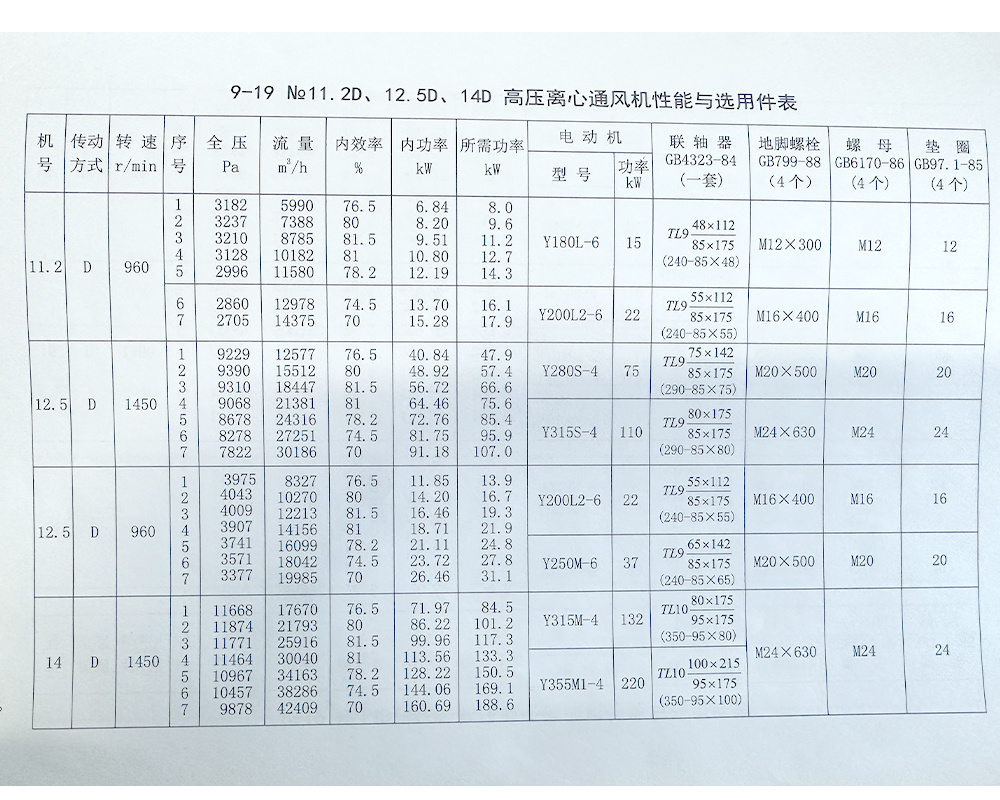

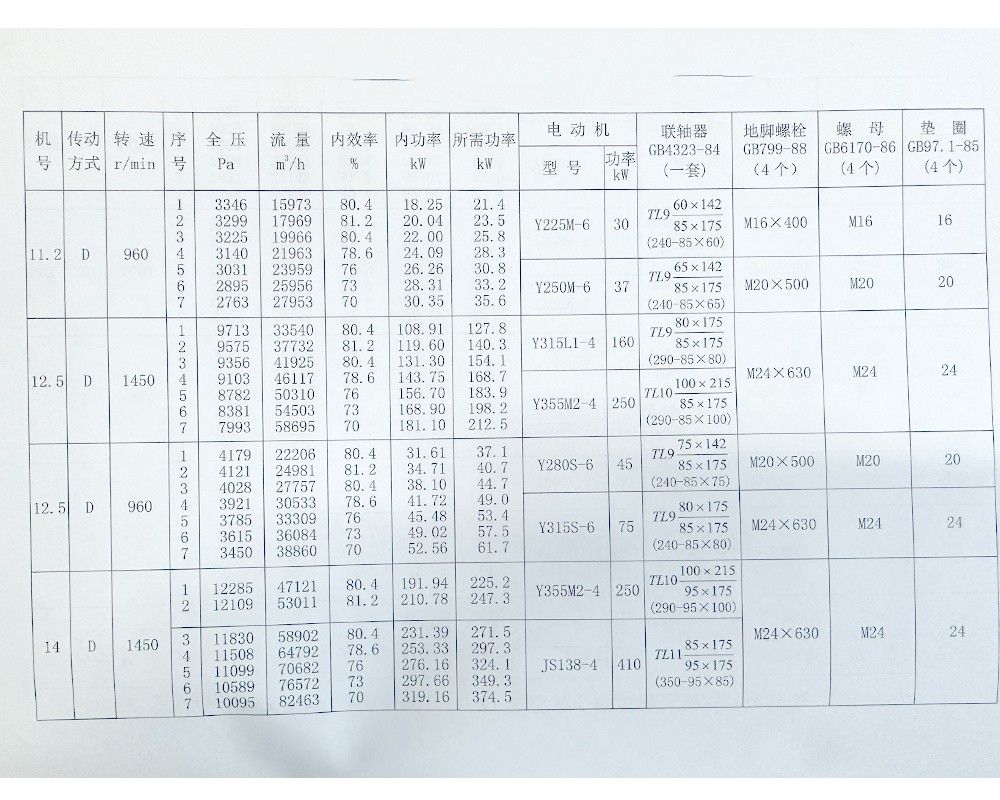

Performance and Selection Table for 9-19 NO11.2D, 12.5D, 14D High-Pressure Centrifugal Fans

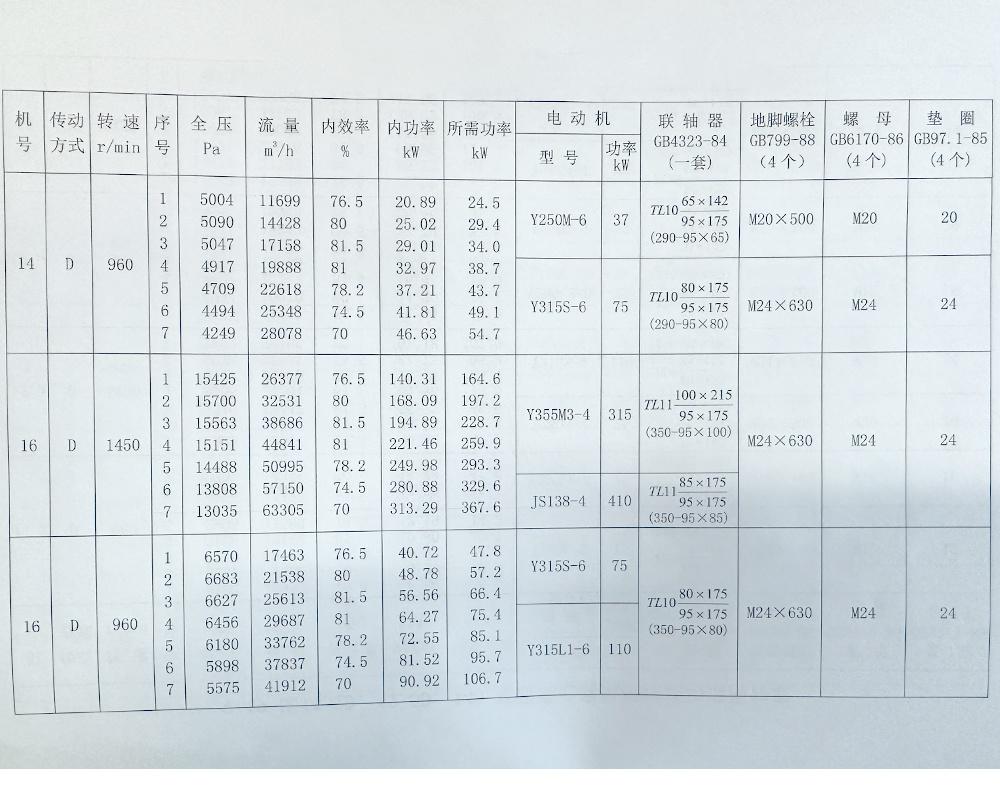

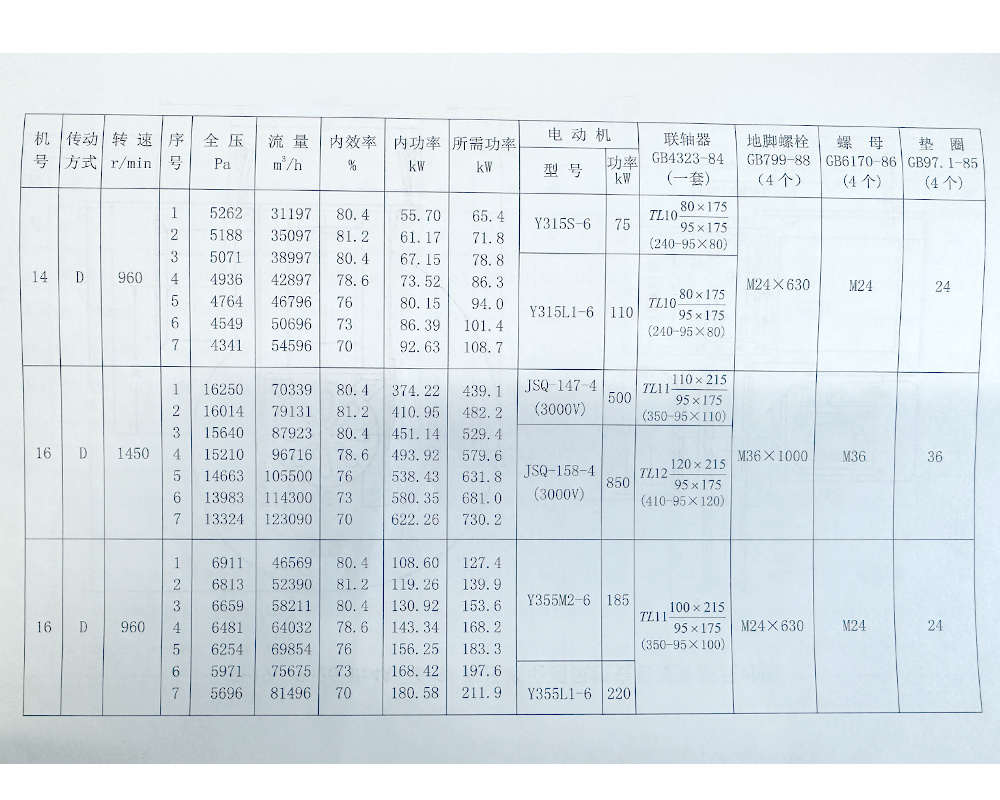

Performance and Selection Table for 9-19 N14D and 16D High-Pressure Centrifugal Fans

Performance and Selection Table for 9-26 N4A, 4.5A, 5A, 5.6A High-Pressure Centrifugal Fans

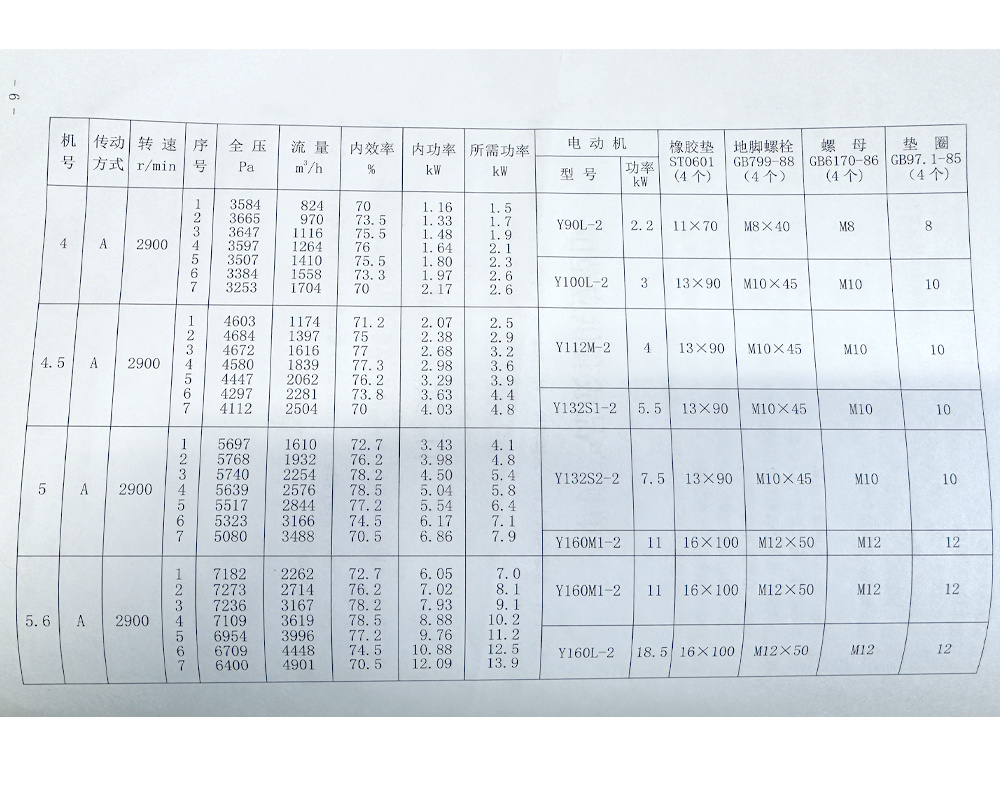

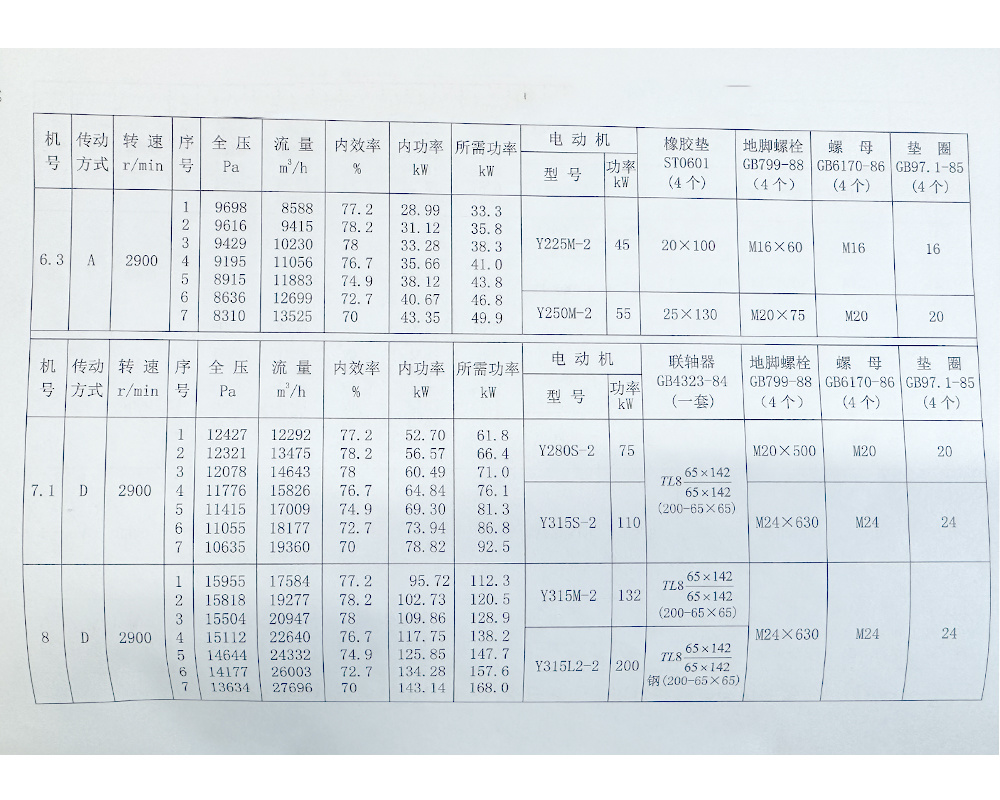

Performance and Selection Table for 9-26 NO6.3A, 7.10, 8D High-Pressure Centrifugal Fans

Performance and Selection Table for 9-26 NO8D, 9D, 10D, 11.2D High-Pressure Centrifugal Fans

Performance and Selection Table for 9-26 NO11.2D, 12.5D, 14D High-Pressure Centrifugal Fans

Performance and Selection Table for 9-26 NO14D, 16D High-Pressure Centrifugal Fans

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Inquiry Message

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products