Hebei Zhengtian Fan Manufacturing Co., Ltd.

Contact Us

E-mail:

youtian@hbztfj.com

WhatsApp:

Add:

Renqiu City, Cangzhou City, Hebei province, discuss Bao township Shoulian village east Yi road east

High-pressure centrifugal fan 9-26

keyword:

- Description

-

Usage

9-19 and 9-26 high-pressure centrifugal fans are generally used for forging furnaces and high-pressure forced ventilation. They can also be widely used for conveying materials, air, and gases that are non-corrosive, non-self-igniting, non-explosive, non-volatile, and do not contain viscous substances. The medium temperature generally does not exceed 50℃ (maximum not exceeding 80℃), and the content of dust and hard particles in the medium is not more than 150mg/m³ 3。

Type

This fan is a single-suction type, and there are 13 models in total: №4, 4.5, 5, 5.6, 6.3, 7.1, 8, 9, 10, 11.2, 12.5, 14, and 16.

This fan is usually made in two types: right-rotating and left-rotating. Viewed from the motor end, the impeller rotating clockwise is called a right-rotating fan, indicated by "right", and the impeller rotating counterclockwise is called a left-rotating fan, indicated by "left".

The outlet position of the fan is indicated by the outlet angle of the casing. Both "left" and "right" can be made into six angles: 0°, 45°, 90°, 135°, 180°, and 225°.

The fan's transmission method is divided into three types: A (N4~6.3), D, and C (7.1~16).

If the above model numbers, rotation direction, outlet angle, and transmission method do not meet your needs, we have the ability to custom-design to your satisfaction.

Structure

N4~6.3 mainly consists of an impeller, casing, inlet, and bracket; N7.1~16 mainly consists of an impeller, casing, inlet, and transmission assembly.

Impeller -- The 9-19 type fan has 12 blades, and the 9-26 type fan has 16 blades, both of which are forward-curved. The maximum peripheral speed of the impeller pressure edge shall not exceed 140m/s. After the impeller is formed, it undergoes static and dynamic balance correction and overspeed operation experiments, so the operation is stable and reliable.

Casing -- Welded from ordinary steel plates into a volute shape.

Inlet -- Made into a convergent streamlined integral structure, fixed to the front cover with bolts.

Transmission assembly -- Consists of a main shaft, bearing box, and coupling. The main shaft is made of high-quality steel, the bearing box has an integral structure, uses rolling bearings, and is lubricated with bearing grease.Maintenance

① The fan and its system are not allowed to operate with faults.

② The fan should be kept and used by a designated person.

③ Regularly clean the dust, dirt, and other impurities inside the fan to prevent rust.

④ Fan maintenance must be carried out after power is cut off, and a designated person should monitor the main switch after power is cut off.

⑤ During fan maintenance and trial operation, children, irrelevant personnel, and people with mobility impairments are prohibited from watching.

⑥ During the trial operation of the fan, no one is allowed to stand within 10 meters of the fan inlet and outlet.

⑦ Before and after repairing the fan, the tools and other supplies should be checked to prevent them from being left in the fan and pipeline.

⑧ Except for lubricating oil, which should be replaced after each overhaul, lubricating oil should be replaced according to the actual situation under normal circumstances.Faults and Causes

1. Severe fan vibration

① The fan shaft and motor shaft are not concentric, and the pulley groove is misaligned;

② Friction between the casing and the impeller or between the inlet and the impeller;

③ Insufficient or unstable foundation rigidity;

④ Loose impeller rivets or impeller deformation;

⑤ Loose fit between the impeller shaft hole and the shaft;

⑥ Loose connecting bolts between the casing, bearing housing, and bracket;

⑦ Poor installation of the fan inlet and outlet pipes, leading to resonance;

⑧ Dust, dirt, blade wear, impeller deformation, shaft bending, etc., causing rotor imbalance.2. Bearing temperature is too high

① Severe vibration of the bearing box;

② Poor quality, deteriorated lubricant, or containing dust, sand, dirt, etc., or insufficient filling;

③ The tightening force of the connecting bolts between the bearing box cover and seat is too large or too small;

④ The main shaft and rolling bearing are installed obliquely, and the front and rear bearings are not concentric;

⑤ Rolling bearing damage or main shaft bending.3. Motor current is too large or temperature rise is too high

① Inlet and outlet pipe valves are not closed during startup;

② Low motor input voltage or single-phase power failure;

③ Affected by severe vibration of the bearing box;

④ Main shaft speed exceeds the rated value;

⑤ The input gas contains viscous substances;

⑥ The ambient temperature is too low, and the proportion is too large.Scope of Supply for Single-Unit Products

1 fan, 1 matching motor, 1 set of foundation bolts (N4~6.3, 4 sets; №7.1 and above, 8 sets), 1 coupling (Na7.1~16).

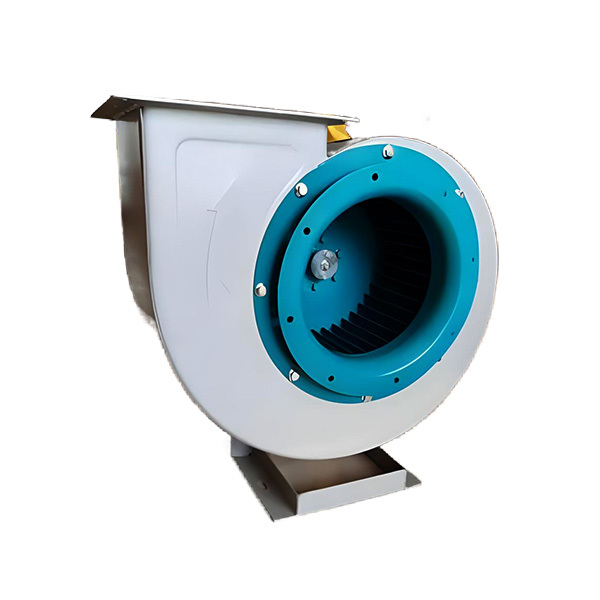

9-19 N4A, 4.5A, 5A and 5.6A High-Pressure Centrifugal Fan Performance and Selection Parts Table

9-19 NO6.3A, 7.1D, 8D High-Pressure Centrifugal Fan Performance and Selection Parts Table

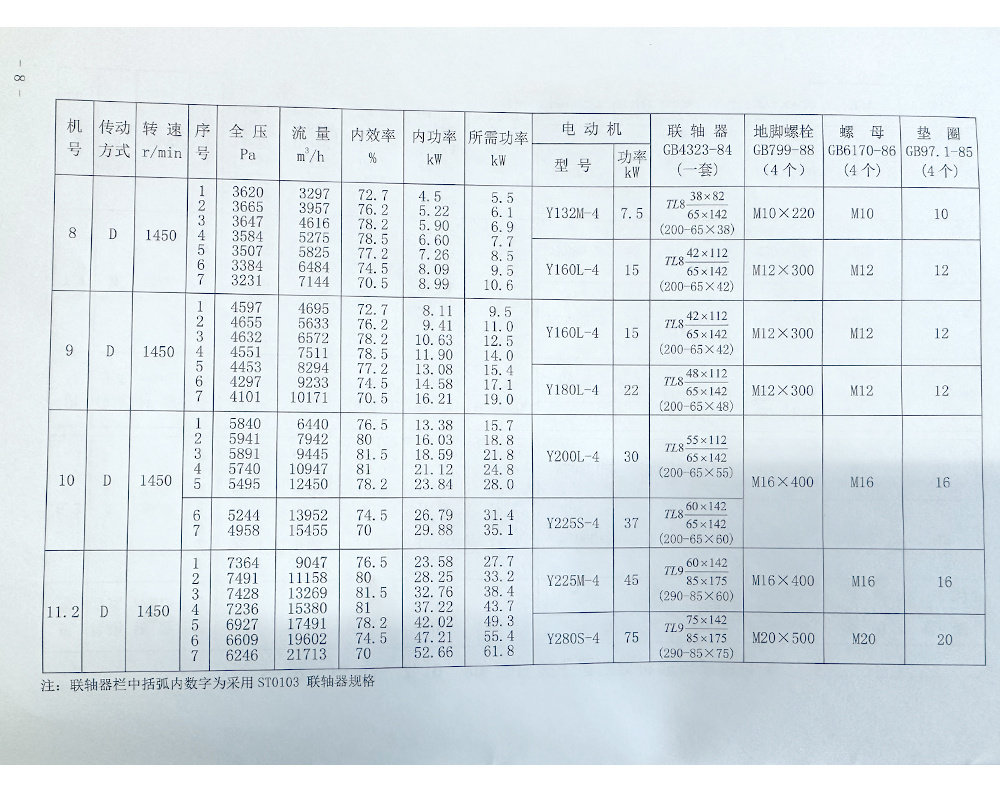

Performance and Selection Table for 9-19 N8D, 9D, 10D, 11.2D High-Pressure Centrifugal Fans

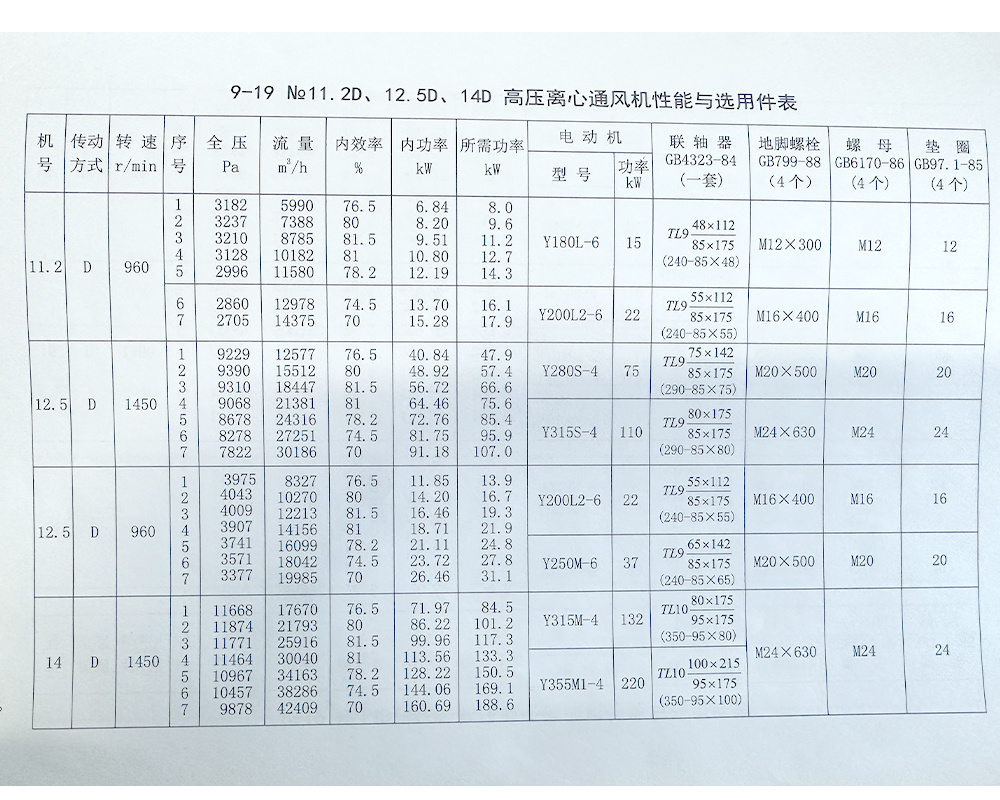

Performance and Selection Table for 9-19 NO11.2D, 12.5D, 14D High-Pressure Centrifugal Fans

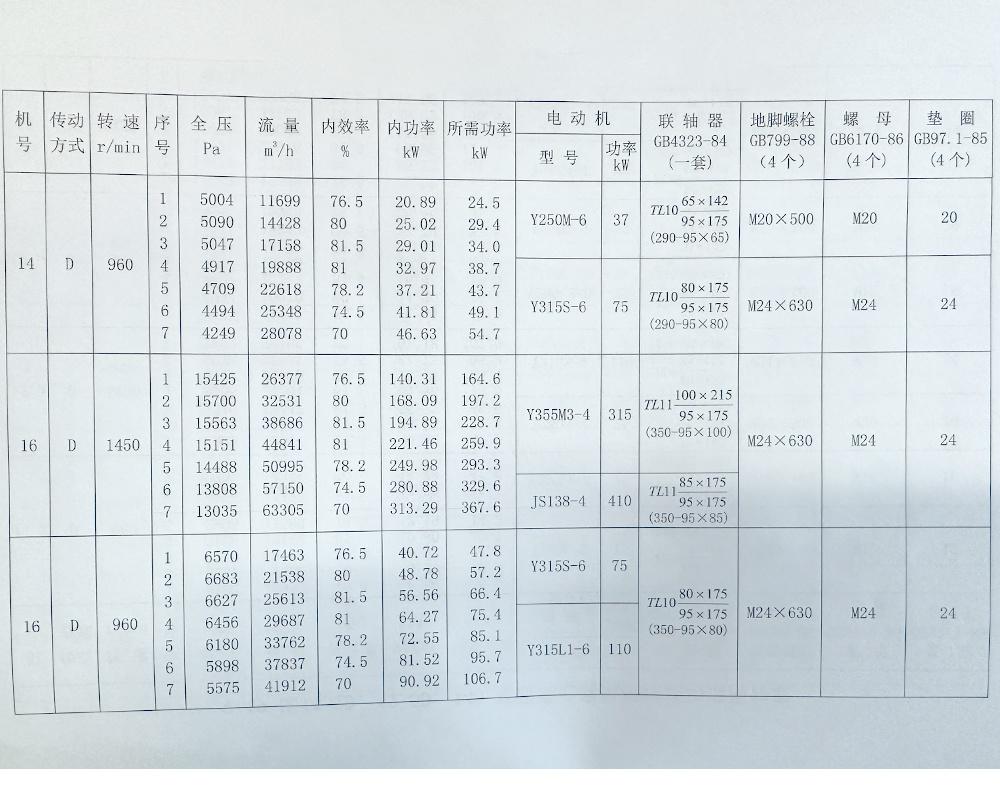

Performance and Selection Table for 9-19 N14D and 16D High-Pressure Centrifugal Fans

Performance and Selection Table for 9-26 N4A, 4.5A, 5A, 5.6A High-Pressure Centrifugal Fans

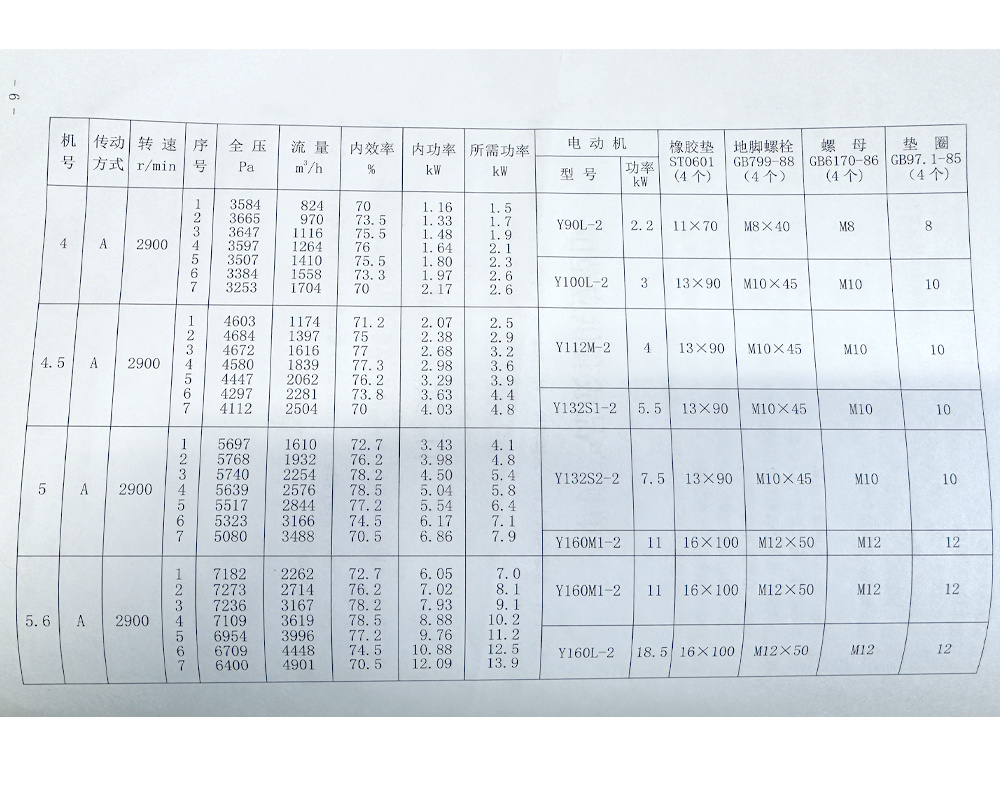

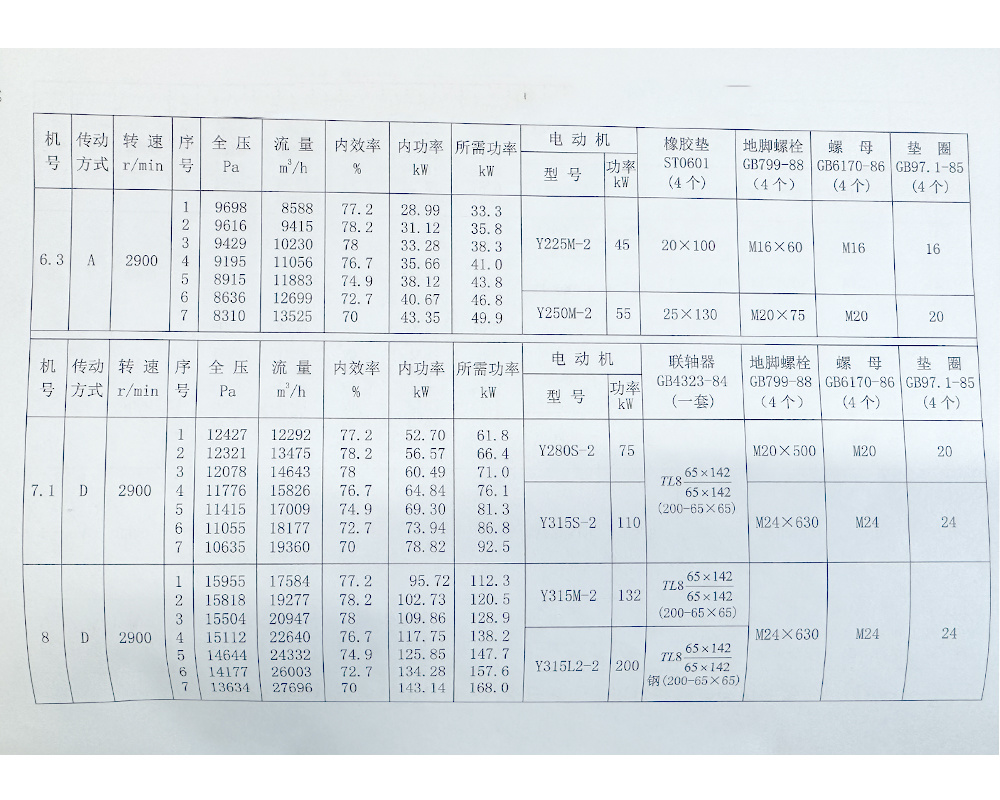

Performance and Selection Table for 9-26 NO6.3A, 7.10, 8D High-Pressure Centrifugal Fans

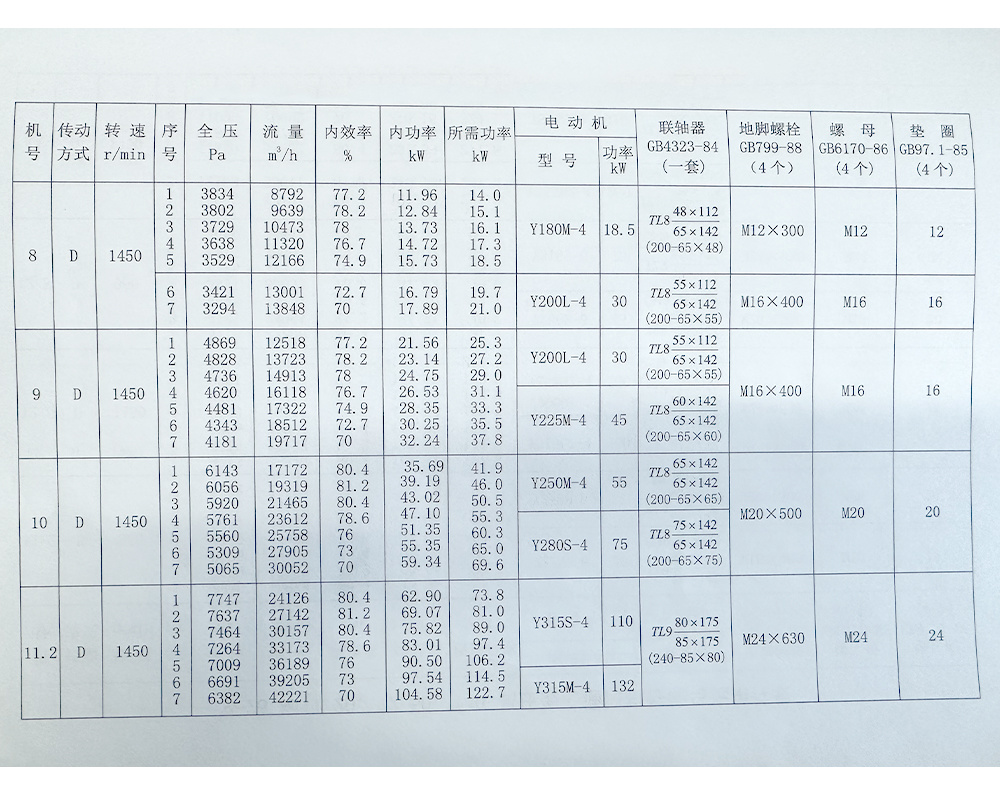

Performance and Selection Table for 9-26 NO8D, 9D, 10D, 11.2D High-Pressure Centrifugal Fans

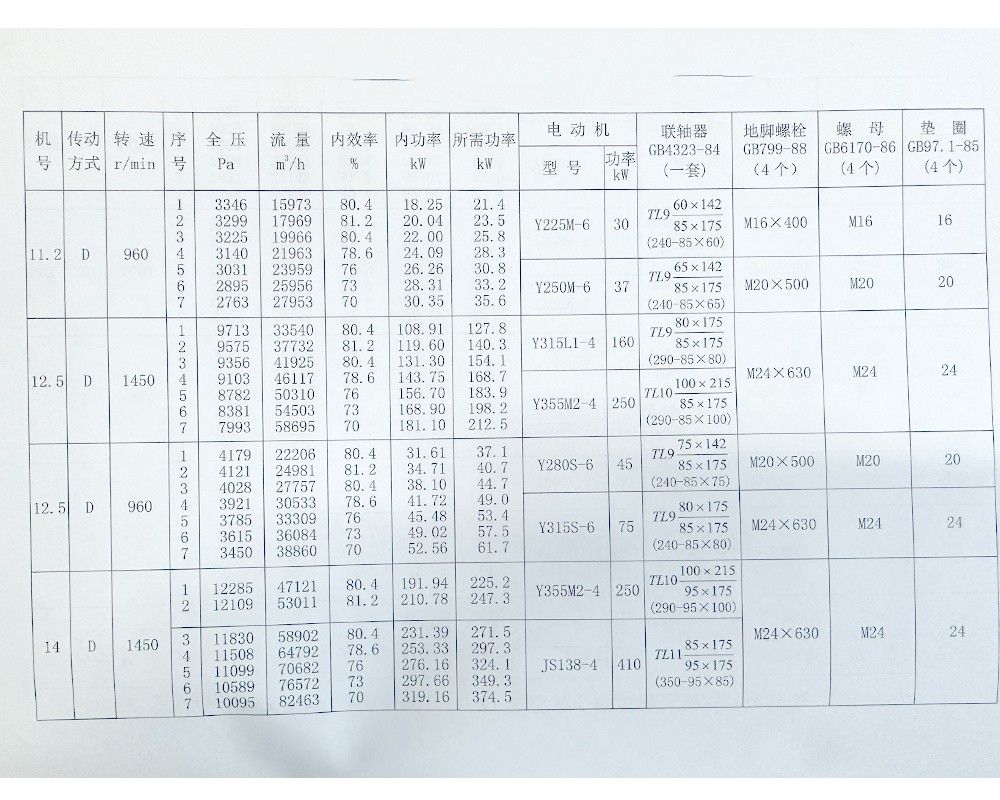

Performance and Selection Table for 9-26 NO11.2D, 12.5D, 14D High-Pressure Centrifugal Fans

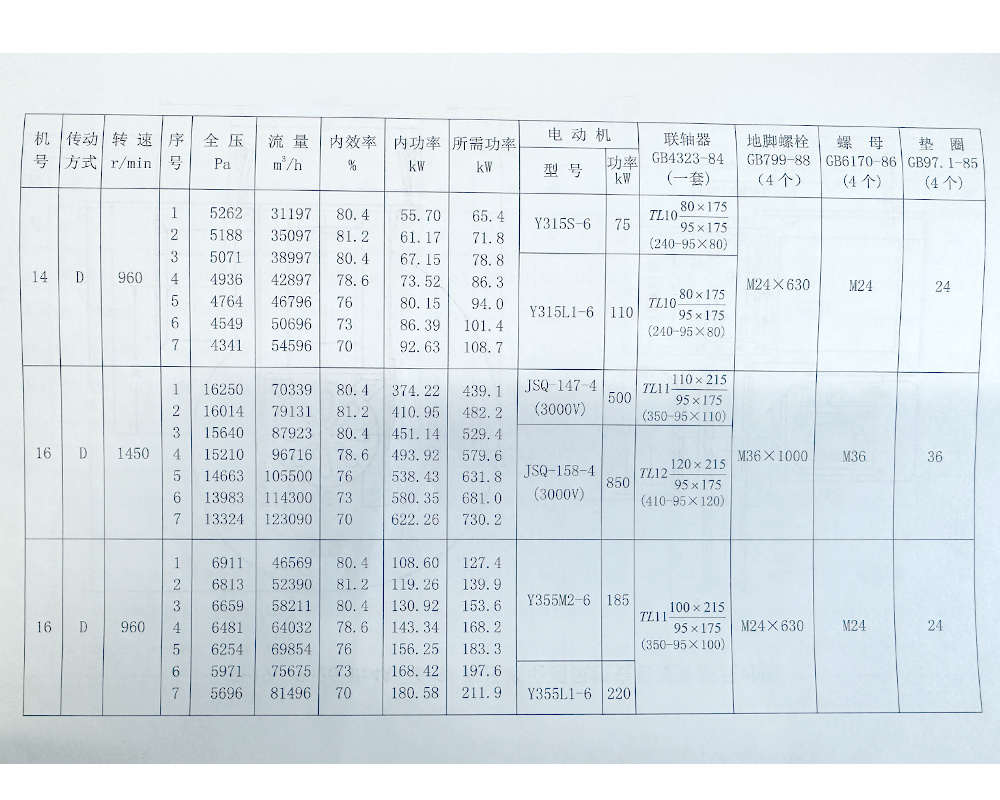

Performance and Selection Table for 9-26 NO14D, 16D High-Pressure Centrifugal Fans

Inquiry Message

Note: Please leave your contact information and our professionals will contact you as soon as possible!

Related Products